1. Project Overview:

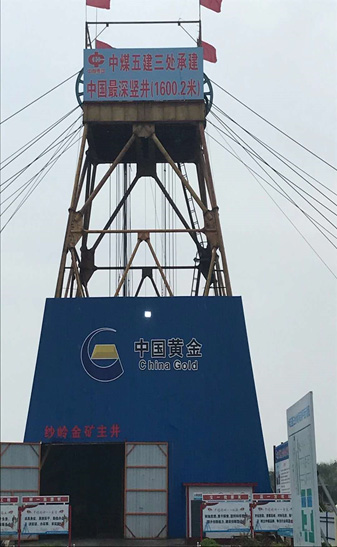

This project is located in Yantai City, Shandong Province, and is a gold mine air systems project for China National Gold Group Co., Ltd.

Mine depth: 1500 meters, it is expected that the temperature of the surrounding rock of the working face will reach 43°C when the shaft reaches the bottom, and the temperature of the working face should be maintained at 25~28°C.

2. Ventilation requirements for underground mine ventilation systems

|

Category

|

Working space

|

shaft of a well net diameter

|

Ventilation parameters

|

Air volume

|

Number of operations

|

|

Auxiliary shaft

|

50 meters

|

8.2 meter

|

8 times/h

|

21000 m3/h

|

8~10 people

|

3. the Program Advantages

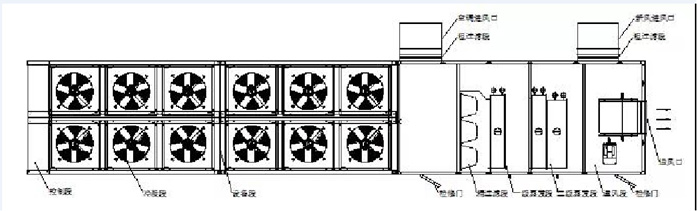

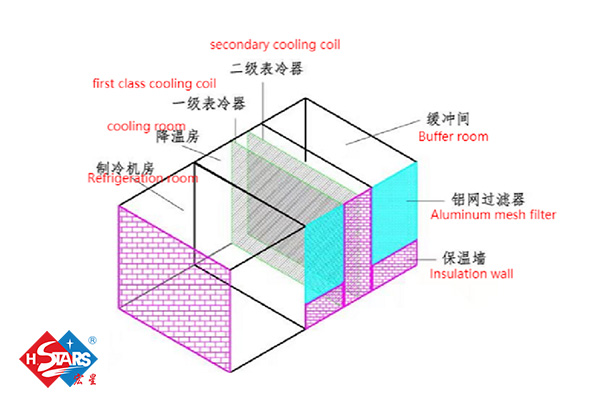

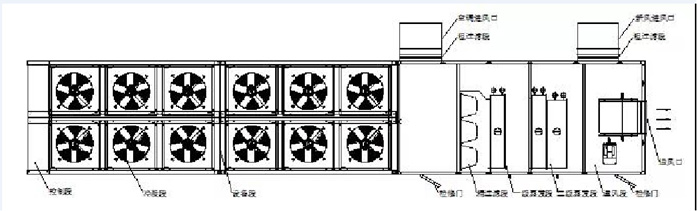

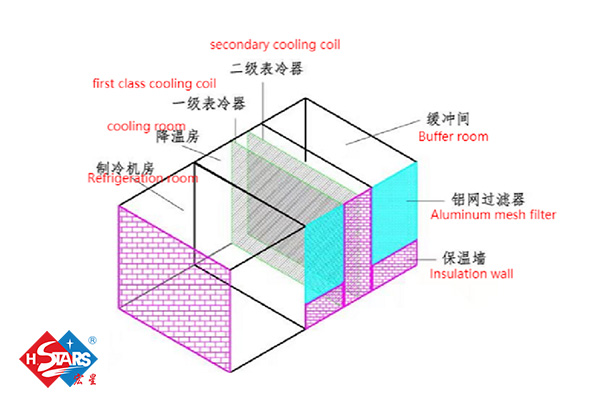

1. Using 3-level cooling, fresh air conditions: 40 degrees in / 14 degrees out.

The air outlet range of the unit: 14~40 degrees

2. The mine air conditioning systems are designed with double air outlets, and fresh air is used for air supply in transitional seasons and winters to reduce operating costs.

3. Easy to clean and adjust: the air inlet is equipped with 304# stainless steel rain-proof elbow, detachable 304# stainless steel insect-proof net, and aluminum alloy manual air volume control valve, 1" plate type washable multi-layer aluminum alloy filter;

4. Precise temperature control: 3-segment coils are matched with proportional and integral valves, temperature controllers,

5. High-quality coil: copper tube + blue wave aluminum fin cold water coil, with slope-shaped stainless steel collecting basin;

6. Italian brand NICOTRA fan, Guangdong Jiangsheng motor, with negative pressure inspection door.

7. The inner and outer panels are color steel plates, and the thickness of the wind cabinet panel: 50mm;

8. The unit uses self-produced high-efficiency fin heat exchangers and hydrophilic aluminum thin fins.

9. Adopt Hanbell compressor, high energy efficiency, stable performance, low noise and low vibration. It has a wide range of operation and can adapt to different operating conditions.

10. The external rotor axial flow fan is adopted, with high air volume, high efficiency, sufficient dynamic pressure, and IP54 protection level.

11. Adopt self-produced high-efficiency flooded evaporator.

12. Unit cop: 3.2

13. Adopt Danfoss electronic expansion valve throttling device to ensure quality.

14. Reliable operation, the unit has a variety of safety protection measures to ensure the safe operation of the unit.

15. Intelligent control: With cloud service system, customers can understand the operation of the unit in an all-round way at any time.

16. Integrated equipment can reduce initial investment costs (civil construction costs and installation costs)

4. Reflect the value of the product

Convince clients of the benefits of our solution, and the value it can create:

Reduce competitors: peer manufacturers do not have this technology accumulation, or are unwilling to do such non-standard customization

Profitable: It is difficult for customers of niche non-standard products with technological advantages to compare prices in the market

Cultivating customer stickiness: To make products that others can't do, as long as there is a project of mine air conditioners, they will think of us at the first time, and they can only find us.

5 Project design focus:

(1) Large load, high temperature and high humidity,

(2) The environment is poor, and the dust around the mine is flying;

(3) The mine roadway is long, the system pressure is large, and the cooling capacity loss is large;

(4) Fresh air circulation, large temperature difference in cooling;

(5) The working conditions of the mining level vary greatly in each period;

(6) It is difficult to control the wind speed of the section of the excavation working face. If the wind speed is too low, the stratification of harmful and toxic gases is easy to occur. If the wind speed is too large, it is easy to cause dust flying and cause secondary pollution.

6. Project configuration

|

Device name

|

Cooling capacity

|

Cooling power

|

Air volume

|

Supply air dynamic pressure

|

Remarks

|

|

Special refrigeration skid for mine

|

600kw

|

165kw

|

21000m3/h

|

7500pa

|

Full fresh air

|

7. Product design functions and features

8. On-site installation