H.Stars Explosion-proof Unit

According to the characteristics of the project, the explosion-proof type can be an explosion-proof type or a positive pressure type. Ex d IIB T4, Ex d IIC T4 can be selected for the explosion-proof grade, and other explosion-proof units can be customized according to user requirements.

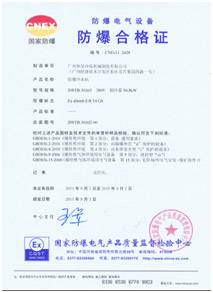

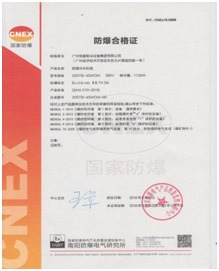

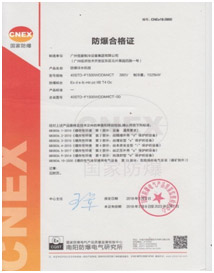

Explosion-proof certificate:

Main components of explosion-proof unit

Explosion-proof compressor

The explosion-proof compressor is produced in accordance with the national standard GB3836 series standard. The explosion-proof mark is Exdib mb IIBT4Gb or Ex d e mb II BT4Gb. It has passed the inspection by the national authorized quality supervision and inspection department and obtained the product explosion-proof certificate. It is mainly suitable for places in Zones 1 and 2 where there are explosive gas mixtures in the air, such as petroleum, chemical, metallurgy, pharmaceutical and defense industries

Explosion-proof electrical box

Explosion-proof mark: Ex d ib II BT4 Gb

The electrical box is divided into explosion-proof type and positive pressure type. The outer wall is welded by steel plate, which has high strength, sturdiness and durability, and is equipped with NWN introduction device. Explosion-proof type: It is fully considered that when the explosive mixture invades its interior and explodes for some reason, it will not cause the explosive mixture outside the electric box to explode.

Positive pressure type: The positive pressure type ventilation and explosion-proof electrical control cabinet adopts dielectric isolation ignition source explosion-proof measures to achieve the purpose of explosion-proof.

Explosion-proof compressor Fan

It is produced in accordance with the requirements of the national standard GB3836 series, and the explosion-proof mark is Exd II CT4Gb. It has passed the inspection by the national authorized quality supervision and inspection department and obtained the product explosion-proof certificate.

Explosion-proof components

Explosion-proof unit series (air-cooled)

|

Standard configuration |

|

|

Compressor |

Explosion-proof screw compressor |

|

Evaporator |

Self-produced high-efficiency evaporator |

|

Condenser |

Self-produced high-efficiency finned condenser |

|

Control electric box |

Explosion-proof control electric box |

|

Throttling device |

Thermal/electronic expansion valve |

|

Fan |

Explosion-proof motor fan |

|

Cable |

Explosion-proof cable |

|

Insulation Materials |

Anti-corrosion, waterproof, mesh insulation layer |

|

Packing |

Reinforced Shrink-wrap Covering |

|

Nozzle connection method |

Flange |

Scroll type Air cooled Explosion-proof unit

|

Standard configuration |

|

|

Compressor |

Explosion-proof screw compressor |

|

Evaporator |

Self-produced high-efficiency evaporator |

|

Condenser |

Self-produced high-efficiency finned condenser |

|

Control electric box |

Explosion-proof control electric box |

|

Throttling device |

Thermal expansion valve |

|

Fan |

Explosion-proof motor fan |

|

Cable |

Explosion-proof cable |

|

Insulation Materials |

Anti-corrosion, waterproof, mesh insulation layer |

|

Packing |

Reinforced Shrink-wrap Covering |

|

Nozzle connection method |

Flange |

Screw type Water cooled Explosion-proof unit

|

Standard configuration |

|

|

Compressor |

Explosion-proof screw compressor |

|

Evaporator |

Self-produced high-efficiency evaporator |

|

Condenser |

Self-produced high-efficiency finned condenser |

|

Control electric box |

Explosion-proof control electric box |

|

Throttling device |

Thermal/electronic expansion valve |

|

Fan |

Explosion-proof motor fan |

|

Cable |

Explosion-proof cable |

|

Insulation Materials |

Anti-corrosion, waterproof, mesh insulation layer |

|

Packing |

Reinforced Shrink-wrap Covering |

Scroll type Water cooled Explosion-proof unit

|

Standard configuration |

|

|

Compressor |

Explosion-proof screw compressor |

|

Evaporator |

Self-produced high-efficiency evaporator |

|

Condenser |

Self-produced high-efficiency finned condenser |

|

Control electric box |

Explosion-proof control electric box |

|

Throttling device |

Thermal expansion valve |

|

Fan |

Explosion-proof motor fan |

|

Cable |

Explosion-proof cable |

|

Insulation Materials |

Anti-corrosion, waterproof, mesh insulation layer |

|

Packing |

Reinforced Shrink-wrap Covering |

Scroll type Water cooled Explosion-proof unit

|

Standard configuration |

|

|

Compressor |

Explosion-proof screw compressor |

|

Evaporator |

Self-produced high-efficiency evaporator |

|

Condenser |

Self-produced high-efficiency finned condenser |

|

Control electric box |

Explosion-proof control electric box |

|

Throttling device |

Thermal expansion valve |

|

Fan |

Explosion-proof motor fan |

|

Cable |

Explosion-proof cable |

|

Insulation Materials |

Anti-corrosion, waterproof, mesh insulation layer |

|

Packing |

Reinforced Shrink-wrap Covering |

Explosion-proof unit series (Evaporative Condenser Chiller)

|

Standard configuration |

|

|

Compressor |

Explosion-proof screw compressor |

|

Evaporator |

Self-produced high-efficiency evaporator |

|

Condenser |

Self-produced high-efficiency finned condenser |

|

Control electric box |

Explosion-proof control electric box |

|

Throttling device |

Thermal/electronic expansion valve |

|

Fan |

Explosion-proof motor fan |

|

Cable |

Explosion-proof cable |

|

Insulation Materials |

Anti-corrosion, waterproof, mesh insulation layer |

|

Packing |

Reinforced Shrink-wrap Covering |

|

Standard configuration |

|

Screw type Evaporative Condenser and Explosion-proof Chiller