For pharmaceutical factories, some production line requires a constant temperature and humidity air conditioning to keep the room ambient for special purpose use. However ,how to design an air conditioning system with stable constant temperature and humidity for the room in pharmaceutical factories?Below are the project reference that H.Stars Group has designed for one the client .

Project overview

Project address: Qujing City, Yunnan Province

Project name: Constant temperature and humidity air conditioner for oral solid preparation workshop

Project requirements:

|

Location |

Area |

Temp requested/℃ |

Humidity requested/% |

Number of air changes |

Cleanliness level |

||

|

Summer |

Winter |

Summer |

Winter |

||||

|

Clean workshop |

1600m2 |

24±2 |

18±2 |

50~70 |

50~70 |

15 times/h |

100,000 level |

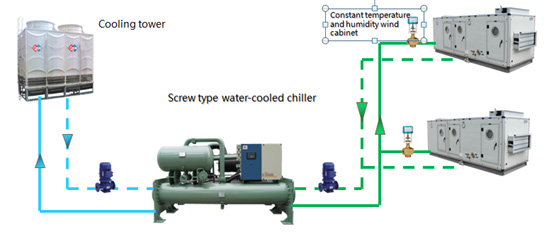

Device Configuration

|

Equipment |

Parameters |

Qty |

Remarks |

|

Screw type water-cooled chiller |

Cooling capacity: 373KW Input power: 70KW |

1 |

|

|

Round cooling tower |

Flow rate: 100m³/h Input power: 2.2KW |

1 |

|

|

Horizontal constant temperature and very humid wind cabinet |

Air volume: 35000m³/h Cooling capacity: 200KW |

2 |

|

|

Vertical cooling water pump |

Flow rate: 91m³/h Head: 27m |

2 |

One for use one for standby |

|

Vertical chilled water pump |

Flow rate: 81m³/h Head: 32m |

2 |

One for use one for standby |

Energy-saving design

1. The air system is designed with a secondary air return system to balance cooling and heating and reduce operating costs.

2. The purification air cabinet adopts the dew point air supply method, which greatly reduces the energy loss caused by dehumidification and reheating, and saves more than 30% of the annual cost compared with the ordinary method.

3. Combination of main and end, combined wind and water adjustment; under the premise of ensuring indoor comfort, the air system and water system are adjusted synchronously based on the end load demand.

4. The fresh air equipment has a clean and dehumidifying function to ensure the quality of fresh air and achieve the purpose of energy saving at the same time .

Solution advantages:

(1) Stable performance: It adopts screw compressor with stable performance, low noise and long service life.

(2) Independent property rights: Unique internal oil return design of the evaporator, low oil return load and high efficiency.

(3) Safe and reliable: The unit is equipped with multiple protections to ensure operational reliability.

(4) High-efficiency and energy-saving: equipped with a full-liquid evaporator, the energy efficiency of the whole machine can reach 5.5.

(5) Intelligent control: The equipment adopts PLC automatic control, no special person is required to supervise the machine room.

H.Stars Group, a Hong Kong group company headquartered in Guangzhou,China, has specialized in manufacturing chiller, heat pump, AHU ,heat exchangers for over 30 years. Welcome to contact us for more at sales@hstars.com.cn