Water Cooled Chiller with Dry Cooler Solution

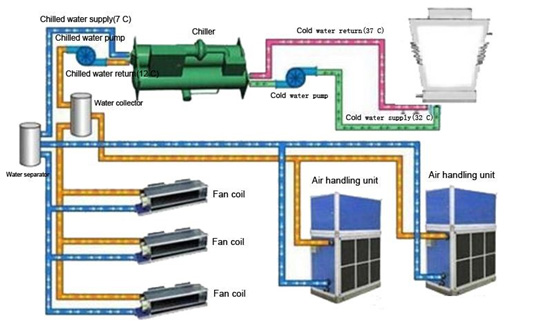

H.Stars Chiller with Dry Cooler sets a new standard in industrial cooling technology. It is specifically designed to provide efficient cooling for a wide range of applications, from commercial buildings to industrial processes in the cold north regions. With advanced features and intelligent design, this chiller offers exceptional performance and energy efficiency.

One of the key features of our Chiller with Dry Cooler is its function in summer as a cooling tower integrated chiller running and in winter it works only with dry cooler fans and compressor not working to save energy, which enhances operational flexibility. The dry cooler allows for easier installation, as it can be placed in a separate location away from the chiller itself. This configuration provides advantages such as noise reduction and space optimization, especially in areas where space is limited.

In addition to its dry cooler, our Chiller with Dry Cooler is equipped with state-of-the-art technology to deliver optimum cooling performance. The advanced control system ensures precise temperature regulation, maximizing energy efficiency and reducing operating costs. The integrated dry cooler enhances cooling efficiency by utilizing ambient air for heat rejection, minimizing water consumption and environmental impact.

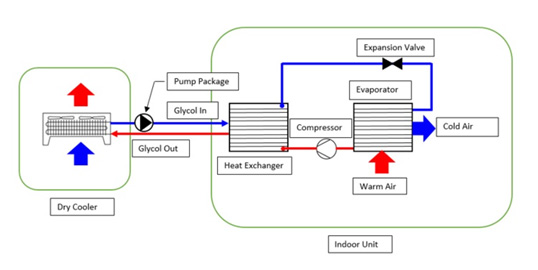

A dry cooler with a glycol system and chiller units keeps all refrigeration cycle components in one enclosure (indoor unit) but replaces the bulky condensing coil with a much smaller heat exchanger, see Fig. 3. The heat exchanger uses flowing glycol (a mixture of water and ethylene glycol, similar to automobile anti-freeze) to collect heat from the refrigerant and transport it away from the space to be cooled. Heat exchangers and glycol pipes are always smaller than condensing coils found in air-cooled systems because the glycol mixture can collect and transport much more heat than air does. The glycol flows via pipes to a dry cooler where the heat is rejected to the outside atmosphere. A pump package (pump, motor, and protective enclosure) is used to circulate the glycol in its loop to and from the glycol-cooled indoor unit and dry cooler (outdoor unit).

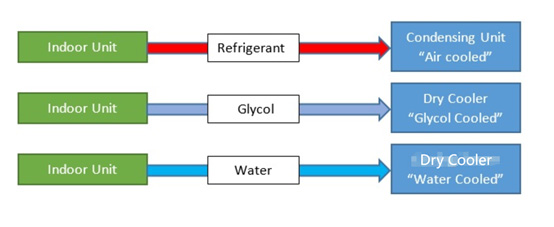

Furthermore, H.Stars Chiller with Dry Cooler system has three options below:

H.Stars boasts a robust and reliable construction, designed to withstand demanding operating conditions. With high-quality components and meticulous craftsmanship, this chiller guarantees long-lasting performance and low maintenance requirements, ensuring peace of mind for our customers.

Whether you require cooling solutions for a data center, manufacturing facility, or commercial space, our Chiller with Dry Cooler offers a versatile and efficient solution. Its compact design, combined with dry cooler capabilities, makes it suitable for various installation scenarios.

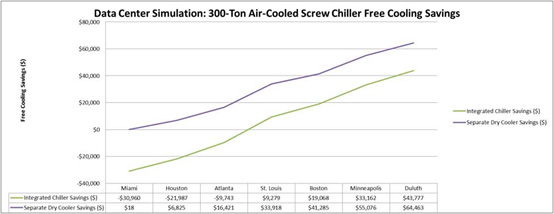

Example: Data Center Simulation: 300-Ton Air-Cooled Screw Chiller Free Cooling Savings

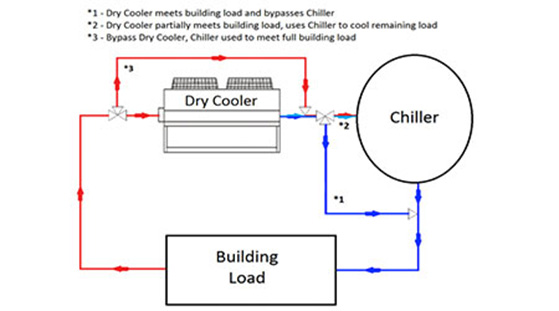

The above Figure also shows all of the locations experienced some net savings annually when using a separate dry cooler to achieve free cooling, with considerably more savings experienced in the cooler climates. Depending on the cost of the dry cooler and location, using a dry cooler will likely show a beneficial payback instead of only using a chiller for annual cooling, with cooler climates experiencing more favorable paybacks.

Another added benefit is that separate dry coolers offer the same opportunity for free cooling to offset chiller run hours, and do not inhibit the chiller performance when the dry cooler is not in use since the dry cooler is physically separate from the chiller’s condenser coil.

This may allow a separate dry cooler to offer additional energy-saving potential in systems like hospitals where the chiller performance derate of integrated free cooling may more than offset the energy savings opportunity of the integrated free-cooling coil.

|

H*VS*91 H*VS*125 H*VS*180 |

Van Dim mm |

* |

H*VS191 H*VS1125 |

H*VS291 H*VS2125 |

H*VS391 H*VS3125 |

H*VS491 H*VS4125 |

H*VS591 H*VS5125 |

H*VS691 H*VS6125 |

H*VS791 H*VS7125 |

H*VS891 H*VS8125 |

H*VS991 H*VS9125 |

H*VS 1091

H*VS 10125 |

|||||||||

|

Rated Capacities (kW) Heat Exchange Surface(n) |

|||||||||||||||||||||

|

Fluid Coolers |

910 |

D |

69kw-1050kw171m 4711㎡(Water/Ta25'c/Tin40'C/Tout35'C) |

||||||||||||||||||

|

1250 |

182kW-2056kw481m 546m(Water/Ta25'c/Tin40'C/Tout35*C) |

||||||||||||||||||||

|

1800 |

398kW-4263kW1326m-19891㎡(Water/Ta25*C/Tin40*C/Tout35*C) |

||||||||||||||||||||

|

Freon Condensers |

910 |

F |

86kW-1167kW171㎡-4711㎡(R404ATa35*C/Tk50*C) |

||||||||||||||||||

|

1250 |

212kW-2340kW 481m-8546m(R404A/Ta35*C/Tk50*C) |

||||||||||||||||||||

|

1800 |

422kW-4085kw1606m-16069㎡(R404A/Ta35*C/Tk50*C) |

||||||||||||||||||||

|

Ammonia Condensers |

910 |

A |

93kW-1234kw 203m-6027㎡(NH3/Ta35*C/Tk50*C) |

||||||||||||||||||

|

1250 |

201kW-2377kW 502m-10046m(NH3/Ta35'C/Tk50*C) |

||||||||||||||||||||

|

1800 |

437kW-4419kw1606㎡-16069㎡(NH3/Ta35'C/Tk50*C) |

||||||||||||||||||||

|

Gas Coolers |

910 |

G |

81kW-1534kw259m-4711㎡(c02/Tair32'c/Tin113'C/P94Bar/Tout34*C |

||||||||||||||||||

|

Oil Coolers |

910 |

O |

65kW-2126kW171㎡-4711㎡(01LIS0 VG 46/Ta35*c/Tin85*C/Tout60*C) |

||||||||||||||||||

|

1250 |

176kW-3548Kw 481㎡-8546㎡(0IL ISO VG 46/Ta35*C/Tin85*C/Tout60*C) |

||||||||||||||||||||

|

Fan Model |

910 |

EC |

W3G910KU2503(2.55kW) or FN91-ZIQ.GLV5P1(3.2kW) |

||||||||||||||||||

|

910 |

AC |

W6D910GB0101(2.02kW) or FN091-SDS.6N.N7P2 (1.85kW) |

|||||||||||||||||||

|

1250 |

EC |

160M2-8P-5.5kW/720RPM/1250 5-5 LP 39*PPG 9W2L |

|||||||||||||||||||

|

1250 |

AC |

160M2-8P-5.5kW/720RPM/1250 5-5 LP 39°PPG 9W2L |

|||||||||||||||||||

|

1800 |

AC |

180L-8P-11kW/720RPM/1790_4-8 31_PPG_9W2L |

|||||||||||||||||||

|

No of Fans |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|||||||||||

|

Overall Dimensions |

910 |

Lenth |

1530 |

2730 |

3930 |

5130 |

6330 |

7530 |

8730 |

9930 |

11130 |

12330 |

|||||||||

|

Width |

1150 |

||||||||||||||||||||

|

Width+Pad |

1400 |

||||||||||||||||||||

|

Height |

1720 |

||||||||||||||||||||

|

Overall Dimensions |

1250 |

Lenth |

1930 |

3530 |

5130 |

6730 |

8330 |

9930 |

11530 |

13130 |

14730 |

16330 |

|||||||||

|

Width |

2000 |

||||||||||||||||||||

|

Width+Pad |

2260 |

||||||||||||||||||||

|

Height |

260 |

||||||||||||||||||||

|

Overall Dimensions |

1800 |

Lenth |

2830 |

5200 |

7600 |

10000 |

12400 |

14800 |

17200 |

19600 |

22000 |

24400 |

|||||||||

|

Width |

2700 |

||||||||||||||||||||

|

Width+Pad |

3000 |

||||||||||||||||||||

|

Height |

3060 |

||||||||||||||||||||

|

H*FD*91 |

Fan Dim mm |

* |

H*FD491 |

H*FD691 |

H*FD891 |

H*FD1091 |

H*FD1291 |

H*FD1491 |

H*FD1691 |

H*FD1891 |

H*FD2091 |

H*FD2291 |

H*FD2491 |

H*FD2691 |

|||||||||||

|

Rated Capacities (kW)Heat Exchange Surface(㎡) |

|||||||||||||||||||||||||

|

Fluid Coolers |

910 |

D |

377kW-3212kw641m-14767㎡(Water/Ta25*c/Tin40'C/Tout35°C) |

||||||||||||||||||||||

|

Freon Condensers |

910 |

F |

339kW-3170kW641m-14767㎡(R404ATa35*C/Tk50'C) |

||||||||||||||||||||||

|

Ammonia Condensers |

910 |

A |

357kW-3279kW 751n-14767m(NH3/Ta35*c/Tk50°C) |

||||||||||||||||||||||

|

Gas Coolers |

910 |

G |

344kW-2311kW 728m-10738㎡(c02/Tair32'c/Tin113*C/P94Bar/Tout34'C |

||||||||||||||||||||||

|

Oil Coolers |

910 |

O |

228kW-5797kW641㎡-14767㎡(0ILIS0G 46/Ta35*C/Tin85*C/Tout60*C) |

||||||||||||||||||||||

|

Fan Model |

910 |

EC |

W3G910KU2503(2.55kW)or FN091-ZIQ.GLV5P1(3.2kW) |

||||||||||||||||||||||

|

910 |

AC |

W6D910GB0101(2.02kW)Or FN091-SDS.6NV7P2(1.85kW) |

|||||||||||||||||||||||

|

No of Fans |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

26 |

28 |

||||||||||||

|

Overall Dimensions |

Lenth |

mm |

2730 |

3930 |

5130 |

6330 |

7530 |

8730 |

9930 |

11130 |

12530 |

14730 |

15930 |

15930 |

17130 |

||||||||||

|

Width |

mm |

2250/2800 |

|||||||||||||||||||||||

|

Width+Pad |

mm |

2510/3060 |

|||||||||||||||||||||||

|

Height |

mm |

2460 |

|||||||||||||||||||||||

In conclusion, H.Stars Chiller with Dry Cooler sets a new benchmark in cooling technology. With its dry cooler, advanced features, and energy efficiency, it provides a reliable and cost-effective solution for your cooling needs. Experience the future of industrial cooling - choose H.Stars Chiller with Dry Cooler for unparalleled performance and efficiency.

Contact us today to learn more about our Chiller with Dry Cooler and how it can benefit your specific application.