The explosion-proof unit is a special air-conditioning equipment, and its components are manufactured in strict accordance with the relevant requirements of the national explosion-proof standard GB3836 and have obtained an explosion-proof certificate. Suitable for use in flammable and explosive special dangerous places and general places. It is widely used in petroleum, chemical, textile, printing, medicine, food and many other industries.

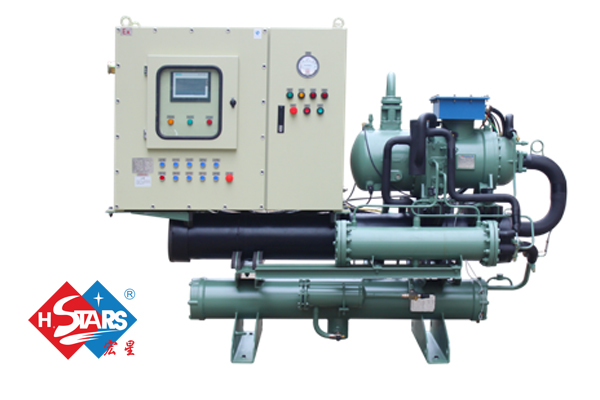

Water-cooled Screw Type Explosion-proof Chiller

Main components of Explosion-proof Water Cooled Screw Chiller

1. Explosion-proof compressorPressurized type: this type of ventilated explosion proof electrical cabinet achieves explosion prevention by isolating ignition source with proper medium.

|

Standard configuration |

|

|

Compressor |

Explosion-proof screw compressor |

|

Evaporator |

Self-produced high-efficiency evaporator |

|

Condenser |

Self-produced high-efficiency condenser |

|

Control electric box |

Explosion-proof control electric box |

|

Throttling device |

Thermal / electronic expansion valve |

|

Cable |

Explosion-proof cable |

|

Insulation Materials |

Anti-corrosion, waterproof, mesh insulation layer |

|

Package |

High-strength plastic sheet |

|

Water outlet connection method |

Flange |

Technical parameter

|

Model |

Nominal cooling capacity |

Input power |

Energy control |

Condenser |

Evaporator |

|||||||

|

KW |

USRT |

Diameter of inlet & outlet pipes inch |

Water flow rate m³/h |

Maximum pressure on water side |

Water pressure drop |

Diameter of inlet & outlet pipes inch |

Water flow rate m³/h |

Maximum pressure on water side |

Water pressure drop |

|||

|

40STD-FB440WS4 |

438 |

125 |

83 |

0,50,75,100 |

5 |

90 |

1 |

53 |

4 |

75 |

1 |

68 |

|

40STD-FB530WS4 |

530 |

151 |

100 |

5 |

109 |

1 |

56 |

5 |

91 |

1 |

70 |

|

|

40STD-FB510WS4

|

615 |

175 |

115 |

5 |

126 |

1 |

54 |

5 |

106 |

1 |

69 |

|

|

40STD-FB690WS4

|

691 |

196 |

128 |

5 |

141 |

1 |

56 |

5 |

119 |

1 |

70 |

|

|

40STD-FB800WS4

|

805 |

229 |

146 |

5 |

164 |

1 |

58 |

5 |

138 |

1 |

72 |

|

|

40STD-FB880WS4

|

866 |

246 |

158 |

6 |

176 |

1 |

58 |

6 |

149 |

1 |

73 |

|

|

40STD-FB940WS4

|

943 |

368 |

172 |

6 |

192 |

1 |

73 |

6 |

162 |

1 |

88 |

|

|

40STD-FB1060WS4

|

1064 |

303 |

195 |

6 |

217 |

1 |

76 |

6 |

183 |

1 |

91 |

|

|

40STD-FB1290WS4

|

1199 |

341 |

219 |

8 |

244 |

1 |

79 |

8 |

206 |

1 |

94 |

|

Special considerations shall be taken for electrical equipment to be used outside the atmosphere conditions mentioned above.

It is recommendable to consider the scenario of co-occurring explosive gas atmosphere and combustible dust atmosphere and to take additional precautions in places where these two may appear together.

Ignition sources not considered in this Part include: adiabatic compression, shock wave, exothermic chemical reaction, spontaneous combustion of dust, open flames, and hot gas/liquid.

Electrical equipment is classified into three types: Type I, Type II, and Type III.

Type I electrical equipment is used in places where coal seam gas exists.

Type II electrical equipment is used in places where there is explosive gas other than coal seam gas.

Type III electrical equipment is used in explosive dust atmospheres other than coal mines.