Introduction:

For businesses and organizations operating ice hockey rinks, maintaining a consistently frozen surface is crucial for safe and enjoyable skating experiences. The cooling system used to keep the ice frozen plays a vital role in this process. In this blog post, we will explore the key elements that contribute to the ice hockey rink surface staying frozen, including the cooling equipment and techniques used in the industry. By understanding these aspects, businesses can ensure the reliable and efficient operation of their ice hockey rinks.

Industrial Cooling Equipment for Ice Hockey Rinks:

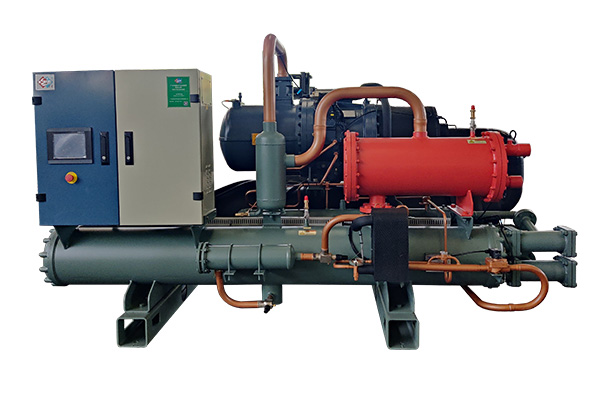

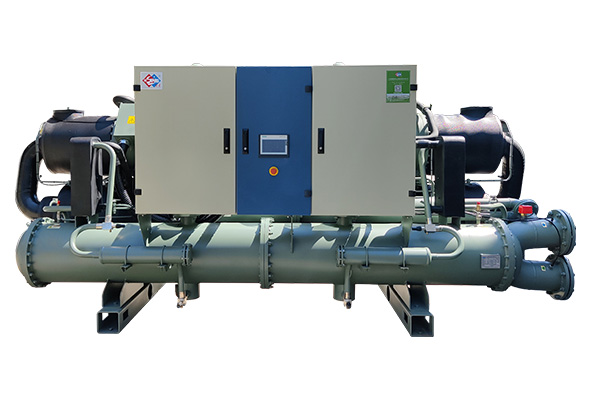

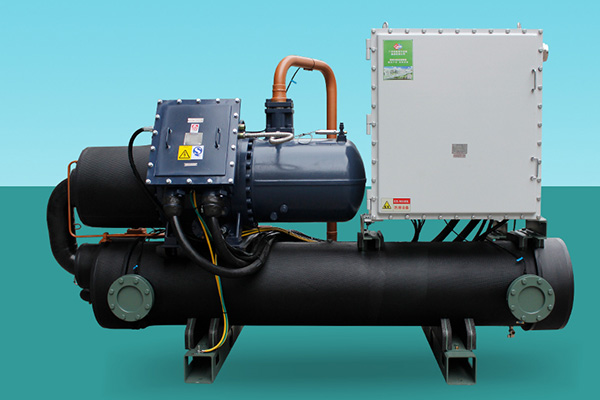

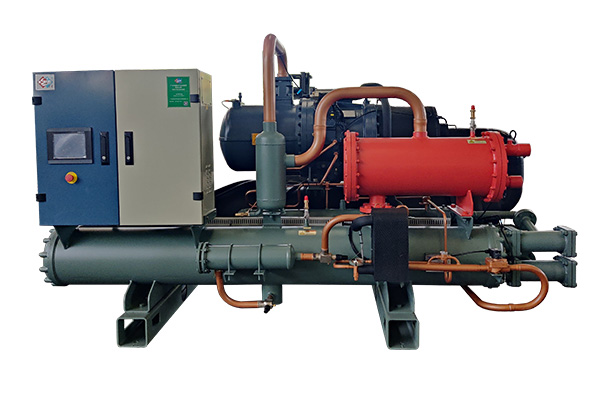

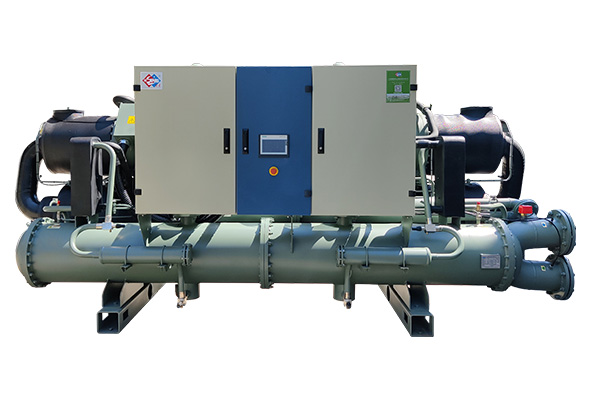

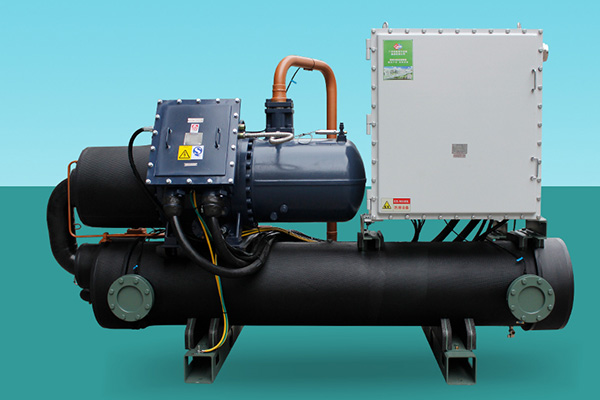

The cooling system of an ice hockey rink is typically powered by industrial cooling equipment, such as a large-scale chiller or cold water machine. These machines are responsible for generating and circulating chilled water through a network of pipes beneath the ice surface. The chilling process cools down the ice, creating a solid and stable surface for skating.

Chilled Brine System: An Essential Component:

Within the ice-making process, a chilled brine system is widely used in ice hockey rinks. Brine is a mixture of water and a cooling agent, usually calcium chloride or ethylene glycol. This chilled brine is cooled to very low temperatures in a chiller, and then it circulates through a series of pipes embedded in the concrete slab beneath the ice surface. The brine's cold temperature efficiently draws heat from the ice, helping it stay frozen.

Glycol Solution for Better Cooling:

To enhance the cooling efficiency and prevent freezing fluctuations, a glycol solution is sometimes added to the water in the ice-making process. Glycol, either propylene or ethylene glycol, lowers the freezing point of the water, preventing it from freezing too quickly during the initial ice formation. This ensures a uniform and stable ice surface, reducing the risk of cracks and imperfections.

Conclusion:

The key to maintaining a consistently frozen ice hockey rink surface lies in the effective cooling system used in the industry. Industrial cooling equipment, such as chillers and cold water machines, play a vital role in generating chilled water or brine that circulates beneath the ice surface. The chilled brine system, along with the use of glycol solutions, ensures a stable and uniform ice surface for safe and enjoyable skating experiences. By investing in reliable and efficient cooling equipment and techniques, businesses can provide their customers with high-quality ice hockey rinks that meet the demands of commercial and recreational skaters alike.

H.Stars Group with 30+ years can help you with our advanced HVAC equipment, If you would like to learn more about Industrial cooling equipment, please leave your inquiry on our website, and our sales team will contact you as soon as possible.

H.Stars Group with 30+ years can help you with our advanced HVAC equipment, If you would like to learn more about Industrial cooling equipment, please leave your inquiry on our website, and our sales team will contact you as soon as possible.