H.Stars Group Achieves Remarkable Success at 2025 AHR MEXICO

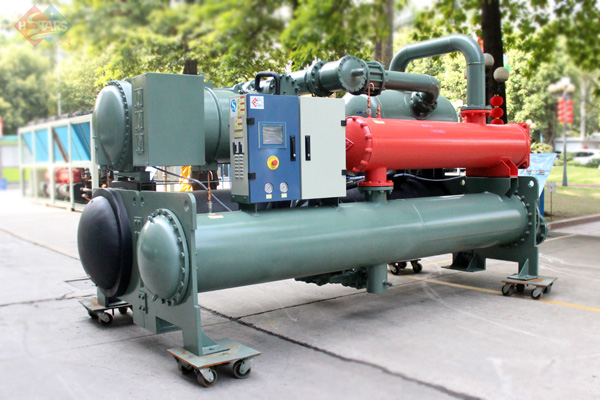

H.Stars Group showcases cutting-edge energy-efficient HVACR solutions at 2025 AHR MEXICO, gains strong market recognition and paves the way for expansion in the Latin American market. Introduction Monterrey, September 2025 - H.Stars Group is proud to announce its successful participation in 2025 AHR EXPO MEXICO, held from September 23 to 25 at the Monterrey International Convention Center. As one of the most influential HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) trade fairs in Latin America, this event attracted industry leaders, technical experts, and professional buyers from Mexico, the United States, Brazil, Argentina, and other countries and regions across the continent. During the exhibition, H.Stars Group showcased its latest energy-efficient HVACR solutions, including high-performance screw chillers and smart air conditioning systems, which garnered strong interest and in-depth inquiries from regional distributors, engineering firms, and end-user enterprises. Mexico's HVACR market, with an annual value of approximately $2.3 billion, is experiencing steady growth driven by urbanization, infrastructure development, and increasing demand for energy-saving and sustainable cooling solutions—presenting significant expansion opportunities for H.Stars Group. This annual exhibition further reinforces H.Stars Group's commitment to the Latin American market. The company will continue to strengthen its market presence in Monterrey (a key regional hub for HVACR trade and manufacturing in northern Mexico) and deepen its engagement with local partners to deliver tailored solutions that meet the unique climate and market needs of the region. Exhibition Review 2. Monterrey, September 2025 - H.Stars Group made a remarkable appearance at 2025 AHR EXPO MEXICO (September 23-25), a flagship event in the Latin American HVACR industry. As a premier platform for innovation and collaboration, the exhibition focused on "Sustainable HVACR Technologies for a Greener Future," gathering global industry leaders and professionals to explore cutting-edge advancements in refrigeration, climate control, and energy-efficient heating solutions. 3. The event featured over 500 exhibitors from more than 30 countries, covering product categories such as chillers, air handlers, heat pumps, and smart HVAC controls. With over 25,000 professional visitors in attendance, 2025 AHR EXPO MEXICO served as a critical bridge for international brands to connect with the fast-growing Latin American market, facilitating knowledge exchange, business negotiations, and technology partnerships—especially in northern Mexico’s industrial and commercial hub of Monterrey. During the three-day event (Sept 23-25), the company welcomed over 15 key customers for in-depth discussions—including 12 pre-scheduled meetings with top regional distributors and engineering firms based in Monterrey and surrounding industrial zones. Multiple new order opportunities are currently under negotiati...

2025-11-04