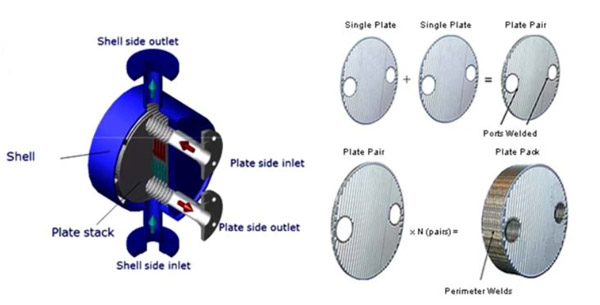

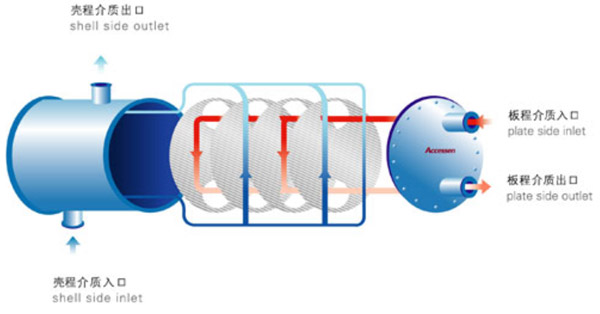

The plate and shell heat exchanger is composed of a plate bundle and a shell composed of a plate group. The corrugated plate group is put into the shell by plasma arc welding, instead of the heat exchange tube of the original shell and tube heat exchanger, with corrugated The plate group is used as the heat exchanger of the heat transfer element. The two fluid media respectively flow through the plate side and the shell side to achieve the purpose of heat exchange. When the fluid flows through the corrugated plates, it can generate a high degree of turbulence in the countercurrent direction, which greatly improves the exchange rate. Thermal efficiency, small terminal temperature difference, good sealing, high temperature and high pressure resistance, compact structure, small size, etc. The products can be widely used in refrigeration and air conditioning, electric power, metallurgy, petrochemical, pharmaceutical, shipbuilding, food and other fields.

The structural are shown in the below

The product can be designed in a detachable form or a fully welded form, the maximum design pressure can reach 10MPa, the design temperature: between -196 degrees to 700 degrees, the plate material is stainless steel 304, 316L, etc., the plate heat exchanger and the shell and tube type are exchanged The advantages of the heater are concentrated in one.

The following is one of the products that our company is producing in cooperation with the plate manufacturer.

Categories

New Blog