Cooling Capacity Range: 7.9kW~118.5kW

Chilled water out let temperature range: 5~20℃

Air cooled scroll water chiller manufacturer

20STB series air cooled chiller adopts brand compressor and electronic control components processing and manufacturing, supporting efficient finned condenser, shell and tube evaporator. Microcomputer control unit, equipped with a variety of protection functions, can accurately control the running status, high reliability. Designed for comfortable air conditioning, cooling applications, suitable for hotels, shopping malls, office buildings and other commercial premises.

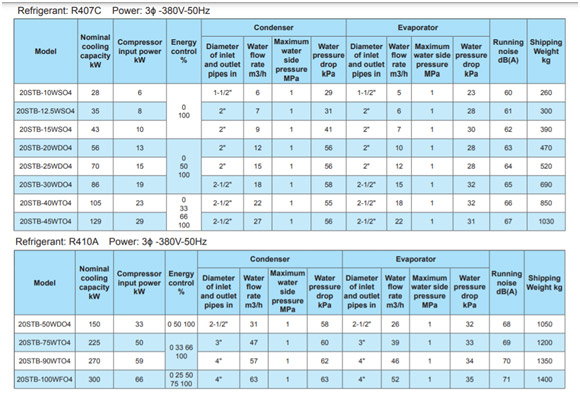

20STB series air cooled chiller parameters:

Outlet water temperature: 5~20℃ Refrigerant: R22, R134a Refrigeration range: 25KW-308KW Heating range:

Scope of application:Food processing, pharmaceutical industry, schools/hospitals, etc

Notes:

1. Nominal cooling capacity: Evaporator water temperature inlet/outlet 12℃ /7℃ , condenser water temperature inlet/outlet 30℃ /35℃ ; fouling coefficient 0.088 ㎡•℃ /kW;

2. Chilled water temperature range: 5℃~ 20℃ ;

3. Cooling water temperature range: 15℃ ~40℃ ;

4. Specifications and dimensions are subject to change due to product improvement without prior notice

Multiple protection measures, reliable operation

The unit has 7 kinds of safety protection measures to ensure the normal operation of the unit.

Unit with single, double circuit design, to meet the different choices of customers. When a single compressor in a dual-circuit unit is faulty, the other compressor can still run normally without affecting the customer's use.

All units have passed the safety test before delivery.

The unit performance meets the enterprise standard.

Intelligent control

The controller adopts high concentration human-machine interface control center, which improves the anti-interference ability of the system. The front and rear panels exchange data through 485 communication interface. The whole system can be installed in one or separate mode.

Siemens PLC controller is optional for ModBus RTU, TCP or S7 communication.

Simple installation

The unit has been filled with refrigerant and lubricating oil before leaving the factory, and the customer only needs to connect the inlet and outlet water pipes and the power supply to run, easy to install.

(3) Product customization

To meet the needs of various parameters, we have gathered more than 20 industry senior R & D engineers to provide customized services for customers with different products.

1, explosion-proof: for the oil, chemical industry, coal industry and other inflammable and explosive special places explosion-proof demand. The unit can be specially designed according to different explosion-proof grade, explosion-proof grade can reach: Ex dIIBT4

2, anti-corrosion: for the application of sewage, sea water, waste gas, waste water and other anti-corrosion media, to provide professional solutions

3, cooling mode: for different cases, provide professional solutions, energy saving, high efficiency, environmental protection and durability

4, spare parts brand: spare parts brand flexible configuration, professional technology, modular replacement, strict control details

5, special conditions: according to the use of the equipment, the application of the scene, process requirements, special design of ultra high temperature water and ultra low temperature water out of the special chillers

6, cloud services: remote monitoring, automatic data integration, safe and reliable, intelligent operation, cost saving, convenient maintenance

(4) Main components

1. Fin Type Heat Exchanger

It adopts the hydrophilic aluminum foil to reduce the adhesion of water on the aluminum foil and greatly improve the heat exchange efficiency. The aluminum fins are packed in the copper and features uniform wind speed. With reasonable array copper pipes, it is installed in "V"-shape to improve heat exchange efficiency and reduce fan noise. The copper tube and aluminum fin are mechanically connected through expansion with high performance and stable heat exchange. It is independently designed and manufactured with strict quality control. Configuring according to the place of use and process, it ensures that the heat transfer coefficient meets the design requirements

2. Compressor

The unit adopts famous brand compressor with middle bearing cap to achieve high energy efficiency and low sound level. The unit runs quieter and more efficient, with the scroll design of "contact-free and wear-free", it can reduce friction.

3. Shell and Tube Heat Exchanger

The copper tube of the evaporator adopts 1.1mm thick copper heat exchange tube, which ensures that all products meet the high requirements of high efficiency, energy saving, safety, strong antifouling ability and durability.

According to the customer's use conditions and water quality factors, different materials of heat exchange tubes can be selected, ensuring the high efficiency and energy saving and service life of the unit. It is independently designed and manufactured with strict quality control. Configuring according to the place of use and process, it ensures that the heat transfer coefficient meets the design requirements.

4.Fan

It adopts special low energy consumption motor patented fan nozzle to improve the air mobility and reduce the noise. Motor waterproof and dustproof grade: IP54, insulation grade: F.

5.Controller

The controller adopts the highly integrated button-type humanmachine interface control center, which greatly improves the antiinterference ability of the system.The product adopts plastic shell, which is easy to install.The front and rear panels exchange data through 485 communication, and the entire system can be integrated or separated.Siemens PLC controller can also be selected to realize ModBus RTU, TCP or S7 communication.

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy