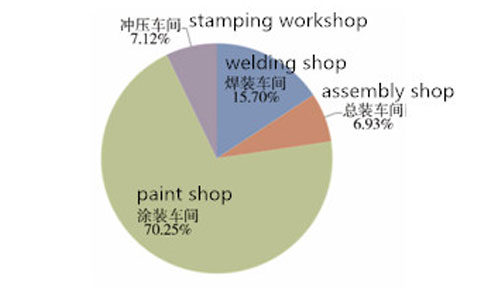

Automobile production and manufacturing process includes stamping, welding, coating and general assembly. According to relevant statistics, coating workshop involves heating, cooling, power, communication control, lighting, etc. energy consumption accounts for a large proportion in the whole manufacturing process (stamping, welding, coating, etc.), accounting for more than 70% of the cost.

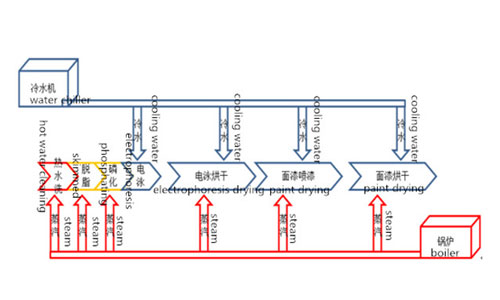

The general process flow of coating workshop is pretreatment, electrophoresis, electrophoresis drying, finishing paint spraying, finishing paint drying and other processes, in which heating and cooling are required. Up to now, the conventional heating and cooling energy are almost gas direct heating steam (high pressure hot water, warm water) and chiller cold water. Each demand is treated independently without integrated treatment of energy recovery and reuse, resulting in energy waste and high energy consumption per unit output.

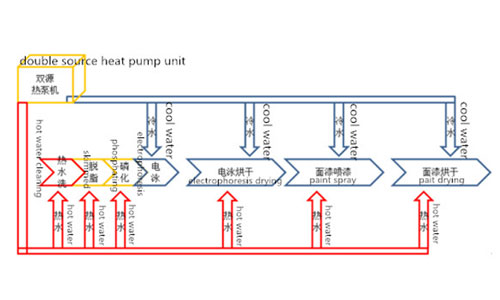

Therefore, in order to effectively solve the problem of energy consumption in painting workshop, how to improve the efficiency of energy consumption, reduce the invalid energy consumption and energy recycling is the key. With the development of heat pump technology, the temperature of high-temperature water can reach 90 degrees, and the innovation of coating materials, coating process and equipment, the thermal energy grade in the coating process is also gradually reduced. The temperature of high-temperature heat pump water has met the demand of thermal energy grade in production.

As a heat transfer equipment from low-level energy to high-level energy, heat pump has a high operating efficiency cop, and will produce two kinds of output, namely, low-temperature and high-temperature goods, during the operation process. Using this physical property, it can meet the hot and cold needs of the coating process, and realize the comprehensive treatment of energy and energy.

The big problem in energy comprehensive treatment is that the cold and hot demands do not match, which often leads to the demand for excessive heat or the demand for excessive super cooling, resulting in the unstable operation of the system. The dual source heat pump is a heat pump equipment with air source and water source as the heat source. When there is a demand for cold water, the water source heat pump operates to achieve dual output and high comprehensive cop. When there is a demand for cold water, the cold water temperature is high When it is lower than a certain value, it will automatically switch to air source heat pump operation to ensure the output of heat energy.

In a practical case, a Toyota Motor Factory has also adopted multiple H.Stars 90℃ dual source heat pump to carry out the technical transformation of energy comprehensive treatment in the painting workshop. Through the comparison of practice, the economic and emission reduction effect is good.

Categories

New Blog

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy