In the design and manufacturing process of UAR shell and tube heat exchangers, how to ensure the encapsulation of the product is a very important topic. At present, there are many seal materials available on the market, the media in the container are diversified, and the physical properties of various media vary greatly. Choosing the right sealing gasket according to the working conditions and medium is the key to ensuring the sealing effect. UAR as one of the largest shell and tube heat exchangers manufacturers in china, is proposing below options for you.

There are many types of gaskets on the market, and they are divided into three categories according to the main materials of their construction: non-metallic, semi-metallic and metallic gaskets. Focus on the non-metallic gasket first. Non-metallic gaskets include rubber gaskets, asbestos gaskets, non-asbestos rubber gaskets, PTFE gaskets and flexible graphite gaskets. Next, we will introduce the characteristics of these sealing materials in detail:

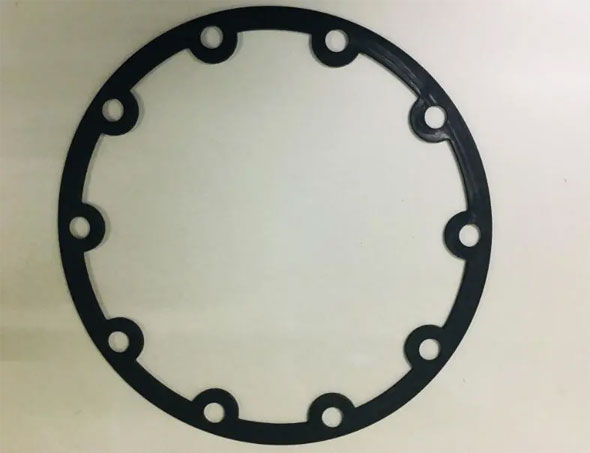

Rubber mat

The main materials for making rubber sheet gaskets are natural rubber, nitrile rubber, neoprene, etc. Rubber is widely used in the sealing of containers because of its compact structure, soft texture, good resilience, easy processing into various shapes, low cost, and easy purchase. It swells and is not resistant to corrosion. It easily ages at high temperatures and loses its resilience.

Asbestos mat

Asbestos has been confirmed to be a carcinogen. As a result of environmental protection, asbestos has been banned and will not be described in detail here;

Non-asbestos gasket is a sealing material formed by calendaring organic fibers such as aramid and plant fibers with nitrile rubber and inorganic minerals at high temperature. As there are few asbestos fibers, it is suitable for asbestos-free gaskets. replacement product. Non-asbestos gaskets (non-asbestos gaskets) have both high strength and good resilience, as well as super strong permeability resistance. They are good environmental protection materials to replace asbestos gaskets under high temperature and high pressure. Due to the characteristics of low density and high compression rate, non-asbestos pads are mostly used for the integration of uneven flange surfaces to achieve sealing.

Polytetrafluoroethylene (referred to as PTFE)

PTFE is known as the "king of plastics" because of its superior chemical resistance, heat resistance, cold resistance, and oil resistance. It is not easy to age, does not burn, and has almost zero water absorption. Teflon gaskets include pure Teflon, filled Teflon or expanded Teflon, etc.

Pure PTFE gasket gasket is a clean sealing product, will not pollute any substances it contacts, can be widely used in food, medicine and other industries; it can withstand a variety of acids, alkalis, salts, grease The corrosion of the solution medium is widely used in petroleum, chemical and other industries.

The most widely used is filled PTFE, in which the filling materials mainly include carbon fiber, copper powder, etc .; after filling, the stability is improved, the thermal conductivity is increased, the linear expansion coefficient is reduced, the creep resistance is improved, the compression strength is increased, and the hardness Increase, wear resistance is improved. In order to change the performance of the gasket, the appropriate filling material can be selected according to the parameters of the heat exchanger's medium and working conditions.

| Gasket parameter comparison table | |||

| Gasket material | Temperature range | Pressure range | Cost |

| Rubber mat | -20℃ ~+200℃ | <2.8MPA | Low |

| Asbestos-free mat | -100℃ ~+1000℃ | <5MPA | Moderate |

| Polytetrafluorothylene | -250℃ ~+250℃ | <10MPA | Higher |

Categories

New Blog