Pharmaceutical factories need to meet the relevant requirements of GMP in the production process, and the temperature, humidity and cleanliness must be controlled within a certain range. Under normal circumstances, when there is no special requirement, the temperature should be controlled between 18 ° C ~ 26 ° C; the relative humidity is controlled at 45% ~ 65%. The clean area of pharmaceutical factories is divided into the ABCD level, that factories of C level and D level are relatively more. It refers to the clean operation zone with less importance in the process of producing sterile drugs. To meet these requirements, a chiller and a combined clean air handling unit are certainly required.

Aseptic workshop in a pharmaceutical factory

The purification air-conditioning system of the pharmaceutical factory uses a large amount of electricity, accounting for about 50% of the total electricity consumption of the factory, so it has caused a great burden for pharmaceutical factories. Therefore, how to reduce the operating cost is particularly important for each pharmaceutical company. One of our clients, which is a refrigerating engineer & designer, have been engaged in the design and project implementation of air-conditioning systems in pharmaceutical factories for more than 20 years. He has participated in the construction of more than 20 pharmaceutical factories. He provided some practical experiences on how to reduce the operating costs of purifying air-conditioning systems in pharmaceutical factories, so that you can make a reference. Following these points can reduce operating costs by 30-40%:

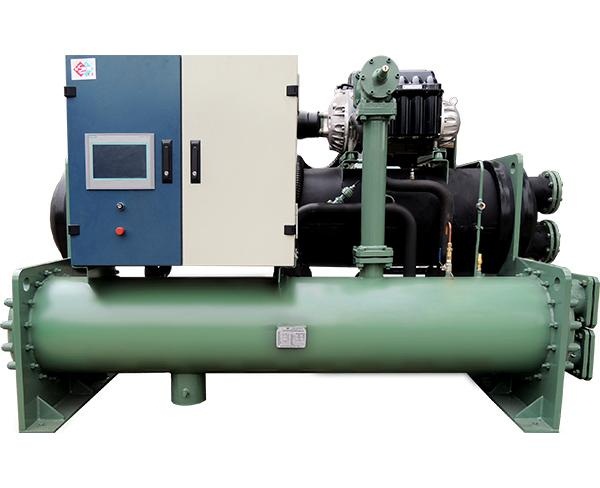

1. Select high-efficiency and energy-saving refrigeration unit, you can choose full-liquid screw unit and centrifugal chiller with good energy saving effect and high energy efficiency ratio. The cooling efficiency is 15% more energy efficient than the average screw chiller.

2. It is necessary to avoid the situation of the power output from the power supply equipment not proportional to the load, because the cold load of the pharmaceutical factory varies greatly depending on the temperature change and the scope of use. Especially in some transitional seasons, the cold load will drop a lot, so when choose the refrigeration unit, try to divide the unit into several pieces of equipment, and try not to choose a large refrigeration unit. The system can automatically select the number of chillers to turn on and the operating load ratio of each chiller. Compared with choosing one or two chillers, the energy saving effect is much better, and the use is safer. Each chiller can be used and ready for each other. If you choose a large unit, it will cause a lot of waste.

3. The combined air conditioning unit adds a fresh air pretreatment table cooler in the fresh air treatment section. The fresh air is first treated to a level of about 13 degrees and mixed with the return air, and then cooled, humidified, and heated to a set air supply state point. Traditional air treatment saves 10%.

Combined air conditioning unit

4. Using the enthalpy difference technology, when the outdoor temperature is lower than 15 degrees in the transitional quarter, the new air volume is increased instead of the chiller cooling, which can reduce the start-up time by 3 months each year and reduce the large amount of operating electricity costs.

5. With fully automatic control, when one of the refrigeration equipments is shut down, the corresponding water pump and cooling tower also stop running, and the temperature and humidity of the workshop are all automatically controlled, which can save 3%-10% of operating costs.

6. Internet of Things mobile APP remote monitoring system, whether you are at home, in the office, on a business trip, or even abroad, you can always open the mobile phone to open the Internet of Things mobile APP remote monitoring system, you can view the data at any time, master the chiller And the operating state of the chilled water circulation system does not require professionals to be on-the-job for 24 hours, which can save a lot of personnel costs.

Categories

New Blog

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy