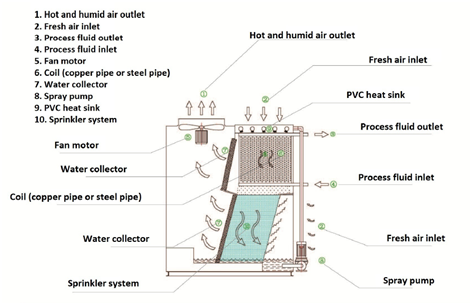

Regarding to water cooled chiller working system, normally it needs to adopt water cooled chiller, cooling tower, water pump or tank etc. To familiar with H.Stars Group water cooled chiller system, here we are introducing you the working principle of square type contra-flow closed circuit cooling towers first.

The working fluid (water, oil or other liquid) flows in the coil clock, the outer wall of the coil is wrapped by the spray water, the heat of the fluid is transmitted through the wall of the tube, and the saturated hot and humid air is formed with the water and the air, and the heat is discharged into the atmosphere by the fan. The parts are blocked and sprayed back to the sink, and the consumption is very small. The spray water reduces the water temperature through the PVC heat-dissipating material during the circulation process, and flows in the same direction as the fresh air. The coil mainly relies on the sensible heat conduction mode. An important feature of the principle is the maximum possible suppression of scale formation on the outer wall of the coil.

Square Contra-flow Closed Cooling Tower Features:

1. Compact structure:

The contra-flow cooling tower has a compact structure, and has more coil heat dissipation area arrangement than the composite flow. It is more suitable for low temperature cooling projects with small temperature difference. Due to our company's rich manufacturing and long-term market engineering experience, it is constantly changing. Type, save more space to increase the heat dissipation area, reduce the floor space, in addition to the production of micro towers, the minimum is only 5 t / h of cooling.

2. Auxiliary equipment available

For some small cooling tower projects, we connect the small counter-flow closed cooling tower with the circulating water pump, circulating water tank and control system to form an integral model, which is convenient for users to use the product. For details, please refer to the parameters of the small cooling tower unittable.

3. The scope of use

It is suitable for low temperature or low temperature difference fluids in cooling fluids.

4. High-efficiency dehydrator (water baffle)

The high-efficiency dehydrator is a standard component of the counter-current closed-circuit cooling tower. It can make the water flow rate less than 0.001%. Therefore, the cooling tower can be installed in areas sensitive to water mist.

The dehydrator is made of corrosion-resistant PVC material, which is installed in the unit inside and is easy to disassemble, so as to repair the internal spray water system and other components.

5. Efficient entry style grid and its dual channel design

The contra-flow cooling tower is made of internally corroded PVC and its dual-channel design prevents splashing and reduces the possibility of algae formation inside the unit. The entrance grille around the sink completely encloses the entire sink, preventing direct sunlight from illuminating the inside of the unit, preventing the growth of algae, reducing water treatment requirements and reducing maintenance costs. At the same time, the inlet grille also has the characteristics of low air resistance, and the water pressure drop can reduce the consumption of ventilation and reduce the running cost of the equipment.

Application in the photo voltaic industry

In the photo voltaic industry, the safety of ingot PCW systems for single crystal furnaces and poly crystalline furnaces is extremely important, so the water quality of circulating water is extremely high.

Application in the machinery industry

High-speed equipment in industrial production will generate heat. These waste heats need to be drained in time to prevent high temperature damage, such as air compressor water jacket, reverse mold cooling, transformer cooling, and engine water jacket cooling.

Application in the air conditioning industry

Evaporative condenser is used in the air-conditioning industry, and the condensing temperature and pressure are significantly reduced. The water-source heat pump system room air-conditioning system.

Application in special industries

Some industries use the cooling of special fluids in because fluids cannot come into contact with the outside world. Quenching oil, sewage, emulsion, etc., need to use closed cooling method, the heat exchanger arm is generally tube box type, to facilitate maintenance.

Water ring heat conditioning system cooling

The safety of the equipment that needs to be cooled in the metallurgical industry clock is important, so the water quality of the circulating water is extremely high, such as the blast furnace circulating water in the iron making, the crystal library in the continuous casting, extremely safe cooling water in an oxygen lance of the electric furnace, etc.

1. The requirements for the environment while using

(1) Locations where has acid exhaust, explosive dust, severe soot, and excessive water vapor should be avoided.

(2) Placed set beside the building and should be kept at a sufficient distance from the air inlet (05-3M, depending on the model)

(3) Placed in the well wall, should be alert to the hot air return caused by the hot air return, special circumstances can consider the air intake device.

2. Piping problems

(1) Piping and pump valves should be installed below the operating water level of the cooling tower to prevent overflow and air inhalation.

(2) When considering the location of the equipment, there should be sufficient pump head, and the pressure loss along the path and the pressure loss of the cooling coil should be considered.

(3) The fluid flanged interface flange pressure is designed to be 1Mpa, all pipes are considered for hangers or supports.

3. Consider fluid compatibility

The fluid to be cooled by the fluid cooler must be compatible with the cooling coil; otherwise it will cause corrosion or blasting of the coil. For example, refrigerant ammonia is not compatible with copper tubes, and brine alkaline water is not compatible with carbon steel tubes and copper tubes.

4. Application in special industries

Some industries use the cooling of special fluids in because fluids cannot come into contact with the outside world. Quenching oil, sewage, emulsion, etc., need to use closed cooling method, the heat exchanger arm is generally tube box type, to facilitate maintenance.

5. Capacity control

For multi-closed closed cooling towers, the number of running towers can be changed.

For towers with multiple fans, the number of fans that can be changed.

6. Spray system requirements

(1) With the operation of the closed cooling tower (evaporation cooling), part of the water evaporates, and the minerals and other impurities left in the water accumulate in the water tank, because the water quality must be checked regularly, and the sewage is cleaned regularly. Good control of water quality and prevention of scaling. The cleaningfor the sink is generally recommended once a week in the summer and once every two weeks in the winter.

(2) Sprinkler water quality requirements: areas with particularly poor water quality should be treated with decontamination (softening), and it is recommended to use stainless steel.

(3) Replenishing amount of spray water

(4) Evaporation ≤ flow rate 08% + water liberation rate ≤ 0.1% + sewage discharge ≤ 03% = circulation flow ≤ 1.2.

Sprinkler system antifreeze needs to consider one of the following three methods:

a. Set indoor insulation water tank, the flow tank has enough capacity, and all the spray water can be collected and moisturized when the machine is stopped.

b. Set the heater in the spray tank, generally using a submerged electric heater steam coil for heat injection

c. When the system stops running, drain the spray water clean.

7. Exhaust

The closed system of the fluid is operated. The steel pipe can be considered as a cooling coil. It can be fully enclosed or semi-closed. The steel pipe is used as a cold coil and must be fully sealed. The fluid is used to replenish the fluid. The gas in the pipe can be the highest in the pipeline. Install the automatic exhaust valve at the point. When the gas pressure reaches the set value, the valve will automatically open the gas. It can also be equipped with a manual exhaust device.

8. Supplementary water

The circulating water of the closed system can be demineralied water, desalinated water or condensed water, etc. due to the requirements of the production process for water quality.

9. The cooling coil of the closed cooling tower antifreeze problem (very important)

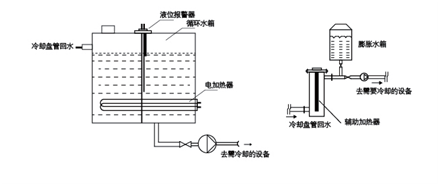

When the temperature is low in winter, the circulating water of the closed system will not freeze even if the circulating water keeps flowing. There must be proper antifreeze measures. Generally, the following two methods are most suitable:

(1) Keep the circulating water at a certain heat load and ensure that the circulating water temperature is not lower than 7 °C (the warm area can be no less than 3 °C). To ensure this heat load, an immersed electric heater can generally be installed in the piping system. Or steam coil heat injector (Figure 1: set the electric heater in the water tank or set the auxiliary heater in the pipeline as shown in Figure 2) while maintaining a small flow of circulating water in the closed system.

(2)

The most effective method is to inject antifreeze, ethylene glycol or propylene

glycol solution in a closed system. The proportion of the filling is as

follows.

Ethylene

glycol(wt%)

0

10

20

30

40

50

58

80

90

100

Freezing point(℃)

-0.0

-4

-8

-15

-24

-36

-48

-47

-29

-13

Categories

New Blog

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy