Chiller shell and tube evaporator

1. Accurate computer matching check, comprehensive optimization design, high heat transfer efficiency. Tested by the National Testing Center, the technical indicators have reached the international advanced level;

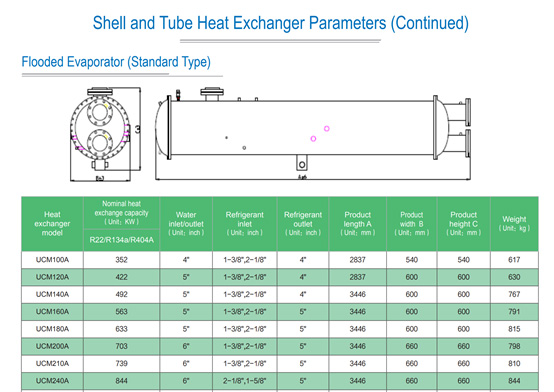

2. HCFC, HFC or other types of refrigerants can be used.Flooded type evaporator means water in tube side and refrigerant in shell side, in the heat transfer between liquid refrigerant and liquid refrigerant, the gaseous refrigerant directly enters the compressor, which greatly improves the heat transfer efficiency.

Technical advantages

Flooded type shell-and-tube evaporator is good quality is first considered, rigorous material selection, beautiful appearance, reasonable structure, individuality, and high efficiency and energy saving

Process advantage

The technology is advanced and reasonable, the welding is stable, the cylinder is pickled, and it has anti-corrosion.

Equipment advantages

All processes choose imported automatic and semi-automatic production. Equipped with a large test platform to ensure superior product performance.

Delivery advantage

More than 50 tons of heat exchange tube inventory, more than 300 finished products inventory, and sufficient spare parts inventory, effectively guarantee product delivery。

Service advantage

We promise: domestic after-sales service will be in place within 48 hours, and in the province within 24 hours.

Characteristic manufacturing process

Pickling process

Using a unique pickling process, the heat exchanger shell is pickled to remove oil, oxide scale and rust, and form a dense phosphate film to protect the shell. Prevent the shell from being oxidized and rusted again during the manufacturing process, thereby effectively ensuring the cleanliness of the refrigeration system.

Drilling technology

The important process of heat exchanger manufacturing adopts high end CNC machining center. Drilling, grooving, and boring use patented tools and are finished by 6 processes. Longterm guarantee the sealing performance of the expanded tube position.

Expanding process

Adopt German CNC tube expansion equipment. According to the tube diameter and wall thickness of the heat exchange tube, the expansion tube head and torque are selected. High-end equipment and rigorous process control effectively guarantee the quality of the tube expansion and ensure the safety of the tube expansion process.

Welding process

Using American Miller welding machine and ASME standard CO2 flux cored welding wire. According to the characteristics of each product, the welding process specification is formulated. Ensure that each weld of the product is beautifully formed and has no defects.

Our Services:

1. After sale service: All of our machine provide long time after-sale service .

2. We accept OEM orders, processing according to buyer’s samples or drawing

3. On-time shipment

4. Product quality protection

5. Payment protection.

Application field:Industrial and commercial field