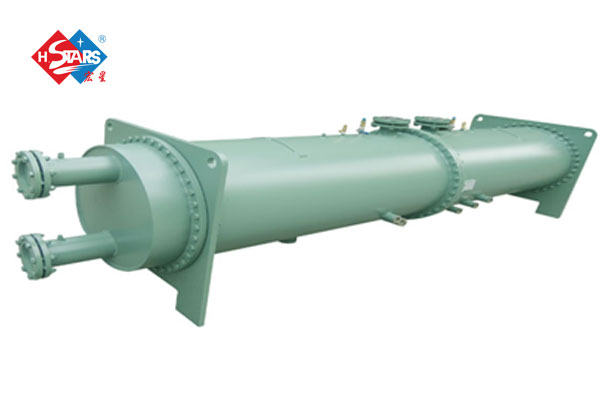

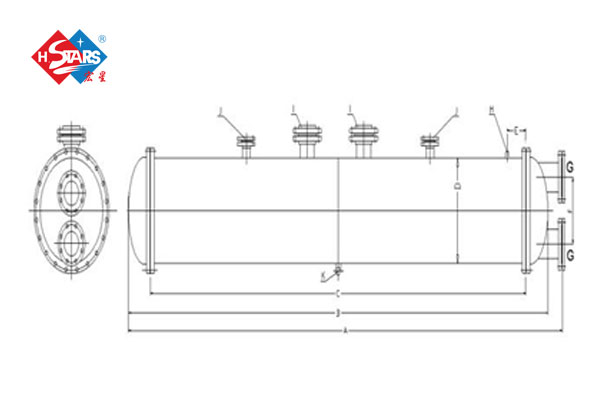

Falling Film Evaporator with Multiple systems

Brief introduction:

The cost-effective falling film evaporator with multiple systems is the most commonly used type of film evaporator due to its wide operating range at 5℃evaporating temperature.

More details:

UAR,as one of the falling film evaporator manufacturers,has been in this filed since 1994. The horizontal falling film evaporator with multiple systems is a new type of high-efficiency heat exchanger. It uses a horizontal falling evaporator device to falling film refrigerant on the surface of the heat exchange tube and evaporate, which greatly improves the heat exchange efficiency of the evaporator; at the same time, it avoids The shortcomings of the raising film evaporator need to be filled with a large amount of refrigerant, which reduces the use cost of the central air conditioner and is more conducive to the oil return of the compressor.

Main benefits:

1. The refrigerant evaporates outside the heat exchange tube with small heat transfer temperature difference and high heat transfer coefficient.

2. Small refrigerant charge, cost-saved and more environmentally friendly.

3. After the refrigerant evaporates and returns to the compressor, the frozen oil will always flow downward and be concentrated at the bottom of the evaporator, which is more convenient for oil return.

4. Applicable to the chiller with multiple compressor systems

5. Compact structure and convenient installation

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy