How to design the best Anti corrosion marine sea water air cooled screw chiller --- for offshore drilling platforms? As what we know , the market with anti corrosion unit has got different class and some of the equipment can only be used for a few years and damaged. Today, let’s check the bellowing design solutions and find out what are the useful information you might gain and learn from.

1. Project Overview:

This project is designed for offshore drilling platforms America, which is used to provide comfortable Screw Type Chiller to the personnel on the offshore drilling platforms.

According to actual need of customer, this project was advised to use our Anti corrosion marine sea water air cooled screw chiller (Copper fin + copper tube +special coating to achieve a salt fog test for 3000 hours) due to corrosive environment on the sea , which can safely extend the life span of the chiller unit and make constant sufficient cooling air to the workshop on the drilling platform.

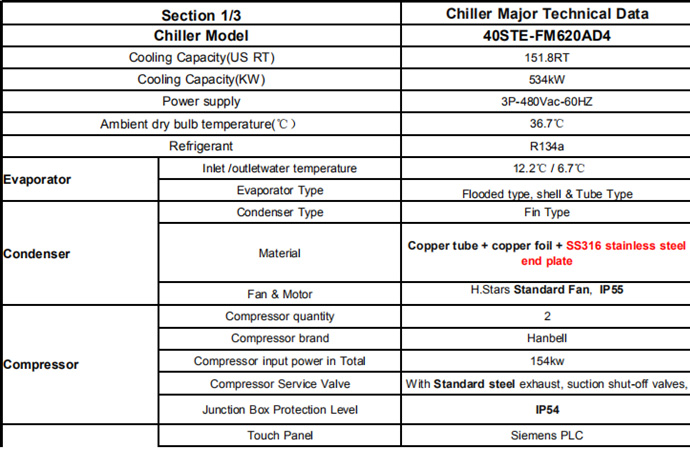

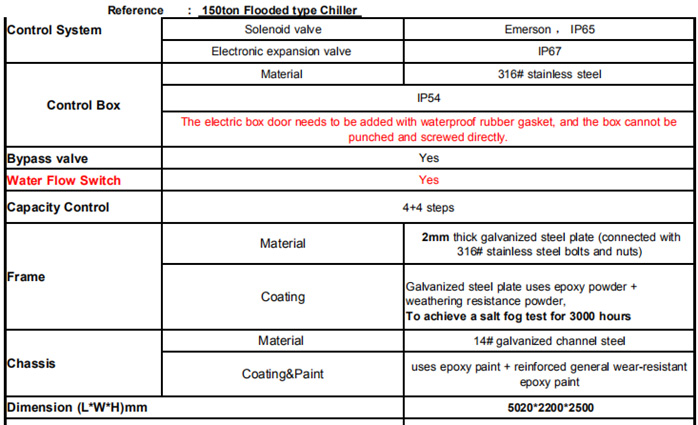

Specification of the Unit 1

Ch150RT Chiller Unit Design

Chiller Installation Site

System Advantages

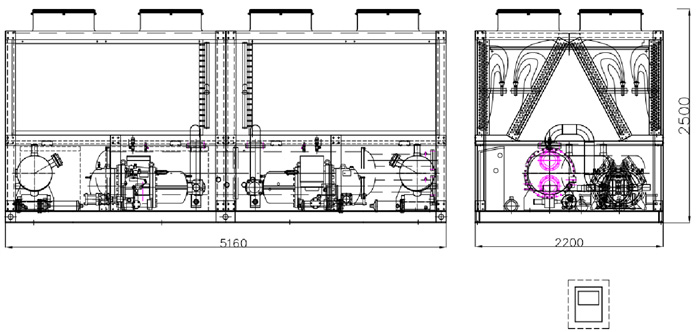

Regarding to the limitation of installation site (Both corrosive air and space limited), the unit has to be designed with anti-corrosion, energy saving and compact size .

It adopts air-cooled Flooded Type Screw Type Chiller with shell and tube heat exchangers

1. Flooded type evaporator reduces energy consumption by 10%-15% compared to dry type evaporator

2. R134a refrigerant :ODP 0 ( no damage to ozone)

3. Copper fins, better anti-corrosion performance

4. IP55 anti-corrosion fan anti-corrosion, waterproof, low failure rate

5. 316 stainless steel electric box more effectively protects electrical components

6. Siemens PLC controller is connected with the customer's central control to realize automatic energy-saving control

7. Galvanized channel steel, special anti-corrosion paint, better anti-corrosion performance, 3000 hours salt spray test to ensure the quality.

H.Stars Group has specialized in customization chiller unit production for 30 years, as one of the top manufacturer and Hongkong brand, we always focus on quality orientation for all clients.For more details, welcome to contact us sales@hstars.com.cn

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy