In industrial and scientific testing, precise temperature control is critical. For a gas meter module test project, the challenge was clear: create two temperature-controlled rooms, one at 5℃ and another at 38℃, to run 4-hour methane-filled tests under strict stability and safety standards. Instead of relying on two separate systems, H.Stars delivered an integrated solution with a single hot-and-cold supply unit.

Project Requirements

Test Needs:

• One 5℃ constant-temperature room

• One 38℃ constant-temperature room

• Test modules placed in sealed boxes, inside methane-filled test rooms

Temperature Control:

• Fluctuation: ±0.5℃

• Uniformity: ±1℃

• Heating rate: reach target in 30 minutes (no load)

Control System:

• Energy-saving water circulation design: cooling at 5℃ recycles heat for 38℃ heating

• At least 4 monitoring probes to ensure temperature uniformity, with separate control and monitoring sensors

• Large circulation fans evenly distributed for stable internal airflow

Safety Measures:

• Explosion-proof equipment for lights and electrical components inside the test rooms

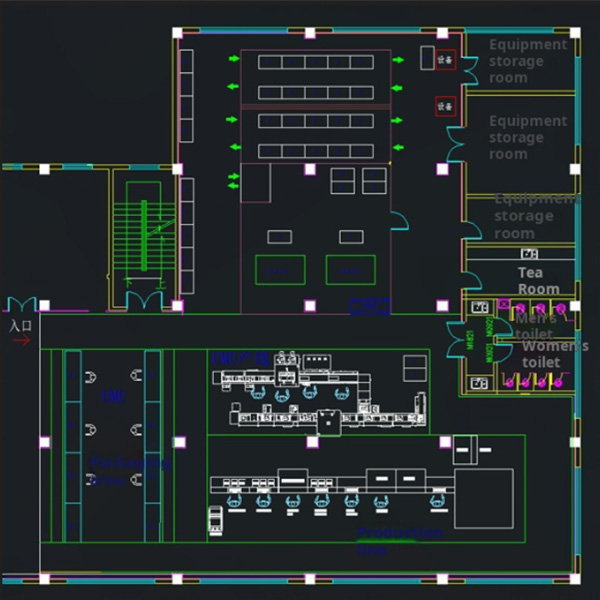

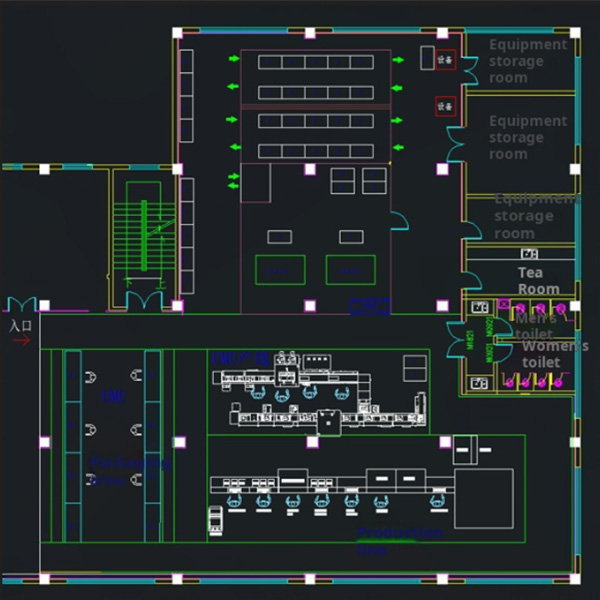

System Configuration

• Hot-and-cold supply unit: 1 set (Cooling capacity: 17.4 kW / Heating capacity: 24 kW)

• Ceiling-type air coolers: 4 sets

• Chilled water pumps: 2 sets

• Hot water pumps: 2 sets

Advantages of the H.Stars Solution

1. Dual-function in one unit – One machine simultaneously provides cooling and heating, meeting both lab needs.

2. Stable water system – Buffer tank with proportional-integral valve ensures precise temperature stability.

3. Backup heating – Electric heater prevents low-load winter issues.

4. Space-saving design – Special cold room doors share tracks, solving installation constraints.

5. Smart automation – Advanced H.Stars control ensures precise and stable lab conditions.

6. Lower maintenance – Refrigerant centralized in one unit, with smaller charge, reduced leak risk, and lower long-term costs compared to multi-split systems.

Conclusion

With H.Stars’ hot-and-cold integrated system, a single solution can achieve both 5℃ cooling and 38℃ heating, providing precise, safe, and energy-efficient temperature control for dual-condition experiments. This innovative design not only reduces equipment costs but also ensures long-term reliability and ease of maintenance.