Industrial Low Temperature Glycol /Brine Chiller

H.Stars screw type low temperature chiller (both air cooled or water cooled available) is used in the production process freezing, refrigeration and industrial cooling. The product model is wide, which can meet the needs of different cooling capacity and temperature requirements. In order to meet customers requirement, H.Stars has launched 40STD cooled low temperature chillers which are widely used in food processing, pharmaceutical, refrigeration and various industrial and commercial cooling systems with special low temperature requirements. Customized chiller service is available . Different power supply of 50HZ and 60HZ are also available .

Main components:

1) Compressor

The compressor adopts a well known brand screw compressor with a 5:6 screw rotor design, which is 20%-30% more efficient than a typical compressor. Applicable to environmentally friendly refrigerant like R134A, R407C,R404A with compressor-specific motor, low failure rate,stable and reliable operation, no fault operation time:50000-80000 hours. The products have obtained two international quality certifications of ISO9001 and ISO9002and multinational patents in Europe and America.

2) Shell and tube evaporator / condenser

The condenser and evaporator are the most important components of the chiller. The quality and manufacturing process determine the heat exchange efficiency and lifespan of the unit. It also represents whether a manufacturer has core technology and intellectual property. H.Stars heat exchanger is self-manufactured with design qualification and pressure vessel production qualification in strict accordance with international standards to ensure product safety and reliability. Guangzhou United A/C & R Co., LTD, as one of H.Stars Group subsidiaries, with more than 20 years of professional experience in manufacturing heat exchangers, with strong technology precipitation, patented technology and independent intellectual property rights, has provided excellent heat exchange equipment and excellent services for many brands in the industry.

3) HMI (Human Machine Interface)

10" / 8" true color touch screen Support USB upgrade. Easy operation and intuitive dynamic operation. Displays control center greatly improves efficiency to provide monitoring, data logging, security protection and convenient operation. The control center has a color liquid crystal display (LCD) and a touch panel. Simply press a single button to display a series of technical data and color maps of the corresponding com

4) Precise water temperature control

The control system monitors the change of the chilled water temperature, senses the past and present water temperature conditions, temperature change rate, and precisely adjusts the chiller according to the monitored conditions to operate according to the set value. The chiller password is divided into multiple levels of passwords, providing the operator with a secure access password to prevent unauthorized changes to the settings.

5) Network of multiple units

Standard MODBUS interface, compatible with various engineering building management systems. Innovative device LAN interface enables multiple devices to be connected into a network to optimize device operation and extend devices lifespan. R_LAN address knob dial, which can set the address of different modules at the site. Engineering electric cabinet can combine in the unit, which greatly reduces the cost on site. The wire controller can achieve non-stop mode switching. Multiple language display, directly show the unit operation, fault conditions, built-in operating instructions, to facilitate the use of the unit. Optional hydraulic module control available.

6) Control Center

Adopts advanced, highly integrated single-chip microcomputer control, greatly improves the anti interference ability of the system. The HMI directly displays the fault content to cooperate with the simple operation interface to timely feedback various maintenance information. Three-phase voltage and current are displayed in real time. The control adopts a combination of protection, real-time control and alarm to protect the safe operation of the unit. The control center can be connected to the network for control, group control and single unit control switching. It can be connected to the Modbus host computer system, enabling users to monitor the running status of the unit in real time at all aspects. Access to cloud service systems.

Product features and functions:

1) The chiller can be designed according to the dimension of the machine room, and it can be delivered to the site by CKD (completely knock down ) or SKD(semi knock down) or the whole unit. Different power supply are available according to different countries and regions ,such as high voltage non-standard chiller .

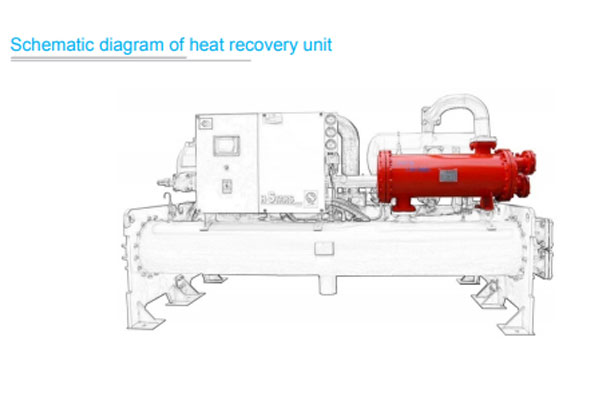

2)Own a heat recovery patent. Waste heat generated in the refrigeration process is recovered by H.Stars patented heat recovery unit to provide free hot water up to 55°C. Boiler replacement to save operating cost.

3)According to user's requirements, H.Stars provides professional advice and selects the most suitable equipment which fits perfectly for each project. Different materials of heat exchange will be recommended to avoid corrosion and leakage according to user’s refrigeration medium used in the project.

4)The variable frequency drive technology greatly improves the Partial load energy efficiency of the chiller ; Evaporative cooling technology with function of high heat exchange efficiency, low investment and save water.

5)Adopting Microcomputer controller, precise control, automatic loading and unloading with multiple functions such as time setting, fault record remote or central monitor. PLC is available for option.

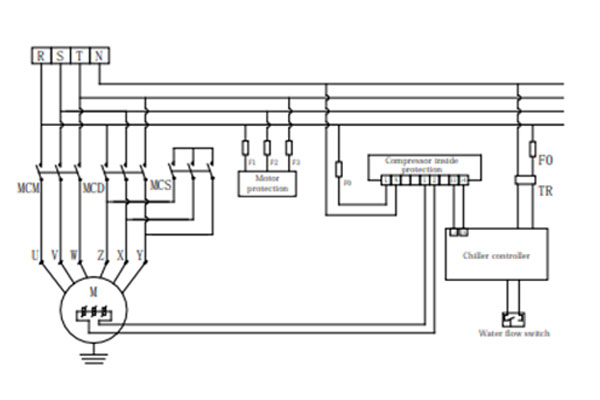

6)The Chiller electrical protection system includes: reverse protection, phase loss protection, compressor and fan overcurrent protection, low temperature protection, high and low voltage protection, water flow protection, etc.

7)The chiller control display can collect various states data of the chiller, and can display operation time, compressor output, inlet and outlet water temperature, and operating status.

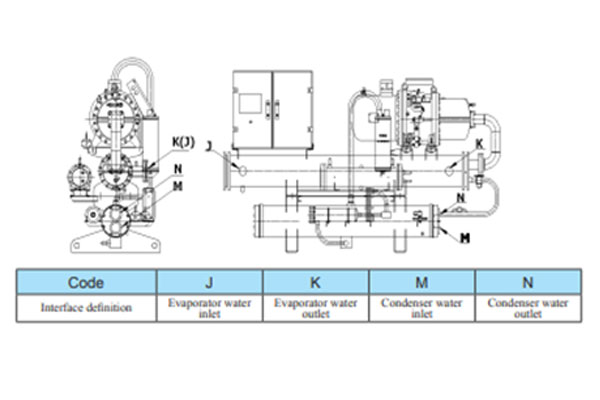

Water connection diagram:

Wiring diagram:

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy