South American white prawn will have reduced feeding and slow growth when the water temperature is lower than 18 °C; when the water temperature is lower than 15 °C, it will stop feeding; when the water temperature is lower than 12 °C, coma will occur. This phenomenon is very common and serious in the mode of breeding wintering South American prawn. At the same time, the water environment in the winter shed is difficult to control, the shrimp disease is frequent, the growth rate is too slow, and it even causes the winter farming failure.

South American white prawn is mainly produced on the South American coast and is now widely bringing in China. Because it is a tropical species, South American white prawn is more afraid of cold. It needs to pay attention to heat preservation when it is cultured in China, otherwise it will freeze to death.

Next, we will introduce a project of the H.Stars Group equipment to help South American white prawn raised healthy in winter.

Ⅰ. Project Overview

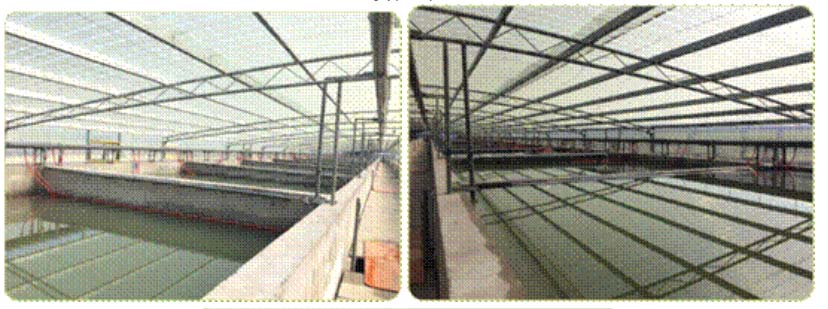

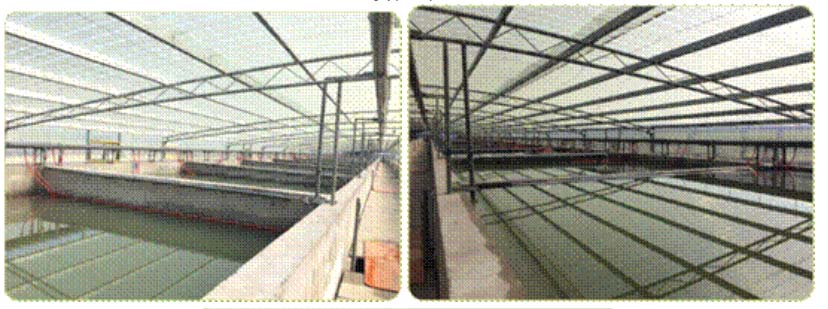

The project is a new ecological park project invested by Anhui Co., Ltd. The project is located in a certain district of Hefei City, Anhui Province, with a planned area of 2million square meters. In the future, it will include fish and shrimp farming, farm gardens, children's playgrounds and theme hotels. The project is for South America white prawn greenhouses to design a second-stage heat pump thermostat system. There are 4 high-level aquaculture pools, each with a surface area of 1200 square meters. It is required to ensure that the water temperature of pawn pond is not lower than 25 °C during winter farming. To meet the constant temperature requirements of the pawn pond water, it is required to ensure the system safe, reliable, energy saving, pollution-free, and intelligent.

Ⅱ, Project plan

1. Design basis

1) Water (ground) source heat pump unit GB/T19409-2013

2) Capacity test method for volumetric and centrifugal water chiller(heat pump) units GB/T10870

3) Screw refrigeration compressor GB/T19410

4) On-site technical exchange data provided by Party A

5) The company's manufacturing technology and engineering experience

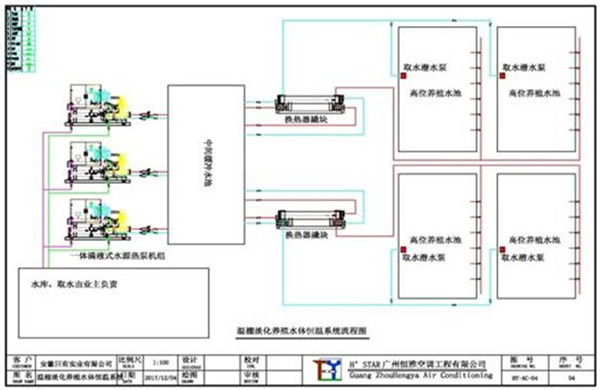

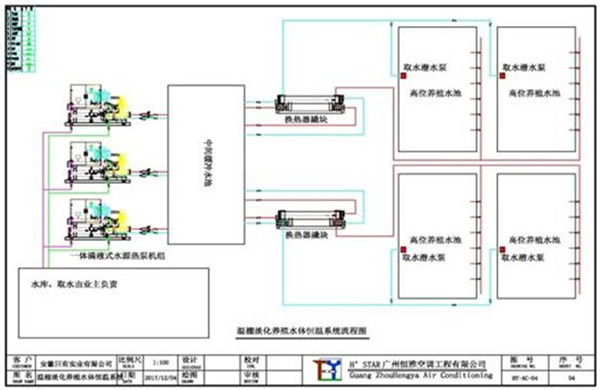

According to the project requirements and the climate conditions of the region, the main design of this program focuses on these three aspects( the use of safety, investment costs, operating costs), with H.Stars Group 's product advantages and manufacturing technology, fully reveal the environmental protection and energy-saving design, to meet the requirements of customer demands, which greatly reduces project investment and operating costs. The entire constant temperature heating system consists of three parts:

1) Heat pump unit; 3 sets of all-in-one flooded type water source heat pump unit with self-contained water circuit module to provide water heating and constant temperature heat source;

2) Intermediate buffer water tank; Designed with a buffer tank with a size of 10m*5m*2m to adjust and prevent the compressor from starting and stopping frequently and storing part of the energy;

3) The heat exchanger module; the heat exchanger, the circulating pump set and the control system are made into a module to exchange heat between the water and the hot water prepared by the heat pump unit, so as to avoid the water directly entering the heat pump unit causing damage or affecting water pollution.

2, equipment configuration instructions

|

Model number

|

Product name

|

Unit

|

Quantity(set)

|

note

|

|

40STD-F690WHS4

|

Integrated

flooded type water source heat pump unit

|

Sets

|

3

|

H.Stars brand

|

|

UWH400B

|

Heat exchangers

|

Sets

|

2

|

H.Stars brand

|

|

Water tank

|

Size 5*10*2(m)

|

Pc

|

1

|

Party A(Clients)

|

Ⅲ, the system diagram

Ⅳ, the machine room scene

Ⅴ. Evaluation and summary

1) Integrated design; the integrated unit combines the heat pump main unit, circulating water pump and electrical control system into a complete set of equipment to realize one-button start-up and reduce engineering installation costs.

2) The screw flooded type water source heat pump unit is high efficient and safe & reliable operation. Under the existing conditions, the COP can reach 6.01 and the height can reach 7.1, which greatly reduces the running cost.

3) The heat pump main unit is completely separated from the pawn pond; an intermediate buffer water tank and a shell-and-tube heat exchanger are added between the pawn pond and the heat pump unit to prevent the heat pump unit from malfunctioning causing the refrigeration oil into the pawn pond ,meanwhile, also avoids the corrosion of the heat pump unit by the alkaline pawn pond.

4) The system adopts multiple units in parallel. The host can automatically start the shutdown group according to the change of the end load, automatically adjust the energy output, save the initial investment cost and make the system more secure.

5) The program realizes full-automatic control, which is integrated into a simple operation mode through micro-computer centralized management, and realizes real-time monitoring of main equipment without one-person management. The control system has a remote monitoring interface that can be upgraded to a cloud service.

Ⅴ. Evaluation and summary

1) Integrated design; the integrated unit combines the heat pump main unit, circulating water pump and electrical control system into a complete set of equipment to realize one-button start-up and reduce engineering installation costs.

2) The screw flooded type water source heat pump unit is high efficient and safe & reliable operation. Under the existing conditions, the COP can reach 6.01 and the height can reach 7.1, which greatly reduces the running cost.

3) The heat pump main unit is completely separated from the pawn pond; an intermediate buffer water tank and a shell-and-tube heat exchanger are added between the pawn pond and the heat pump unit to prevent the heat pump unit from malfunctioning causing the refrigeration oil into the pawn pond ,meanwhile, also avoids the corrosion of the heat pump unit by the alkaline pawn pond.

4) The system adopts multiple units in parallel. The host can automatically start the shutdown group according to the change of the end load, automatically adjust the energy output, save the initial investment cost and make the system more secure.

5) The program realizes full-automatic control, which is integrated into a simple operation mode through micro-computer centralized management, and realizes real-time monitoring of main equipment without one-person management. The control system has a remote monitoring interface that can be upgraded to a cloud service.

6) The system adopts a flooded type screw type water source heat pump unit. The unit sets two functions of cooling and heating. In addition to meeting the temperature of the pawn pond, it can also be used for later salmon farming.

Other related products :shell and tube heat exchanger