Introduction:

When it comes to industrial cooling needs, selecting the right glycol chiller is crucial for optimal performance and efficiency. Whether you require a glycol chiller for a specific project or application, understanding its uses, choosing the appropriate capacity, and sizing it correctly are essential factors to consider. In this blog post, we will explore these three key aspects to guide you in choosing the right glycol chiller for your industrial cooling requirements.

What Can a Glycol Chiller Be Used For?

A glycol chiller is a versatile cooling solution with various applications across industries. Some common uses of a glycol chiller include:

Process Cooling: Glycol chillers are widely used for cooling industrial processes, such as

chemical manufacturing,

food and beverage production,

pharmaceuticals, and

plastics processing. They help maintain precise temperature control, ensuring product quality and process efficiency.

HVAC Systems: Glycol chillers are utilized in large-scale heating, ventilation, and air conditioning (HVAC) systems, providing cooling for commercial buildings, data centers, and other facilities. They help maintain comfortable indoor temperatures and prevent overheating of equipment.

Laboratory Equipment: Glycol chillers are employed in laboratories to cool scientific instruments, analytical devices, and experimental setups, ensuring accurate and stable temperature conditions for reliable results.

How to Choose the Right Capacity of a Glycol Chiller?

Selecting the appropriate capacity of a

glycol chiller is vital to meet your cooling requirements effectively. Consider the following factors when choosing the right capacity:

Cooling Load: Determine the heat load of your specific application or process. Calculate the amount of heat that needs to be removed within a given time frame. Factors such as equipment size, heat generation rate, and required temperature range are crucial in determining the cooling load.

Ambient Conditions: Consider the ambient temperature and humidity of the environment where the chiller will be installed. High ambient temperatures and humidity levels can affect the cooling capacity required.

Expansion Plans: Anticipate any future expansion or increased cooling demands. It is advisable to choose a glycol chiller with a capacity that allows for potential growth in your system or project.

Efficiency and Energy Consumption: Evaluate the chiller's efficiency, as indicated by its Coefficient of Performance (COP) and energy consumption. A more efficient chiller can provide cost savings and environmental benefits.

How to Size a Glycol Chiller in My Project?

Sizing a glycol chiller accurately involves comprehensive calculations to ensure optimal cooling performance. It is recommended to consult with a professional or utilize specialized software for accurate sizing. The sizing process typically involves:

Collecting Data: Gather information about your cooling requirements, such as equipment specifications, cooling load calculations, temperature range, and desired fluid flow rate.

Conducting Heat Load Calculations: Perform heat load calculations to determine the amount of heat that needs to be removed based on your specific application. Factors such as ambient conditions, equipment heat dissipation, and process requirements should be considered.

Chiller Selection: Based on the heat load calculations, select a glycol chiller with the appropriate cooling capacity, taking into account factors like efficiency, reliability, and manufacturer specifications.

Conclusion:

Choosing the right glycol chiller is crucial for efficient industrial cooling. Understanding its applications, selecting the appropriate capacity based on cooling load and ambient conditions, and sizing it accurately for your project are key considerations. By carefully evaluating these factors and seeking professional guidance, you can ensure that your glycol chiller meets your cooling needs effectively, providing reliable and efficient cooling performance in your industrial applications.

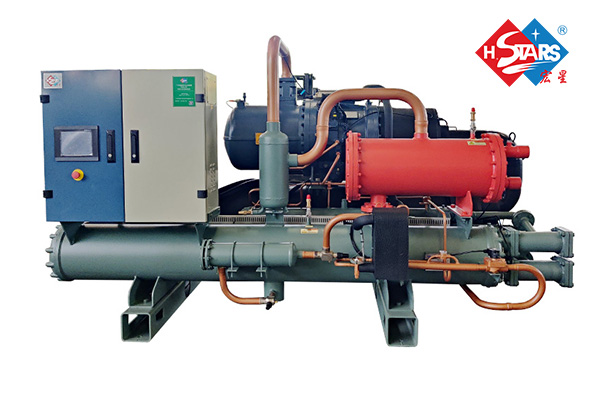

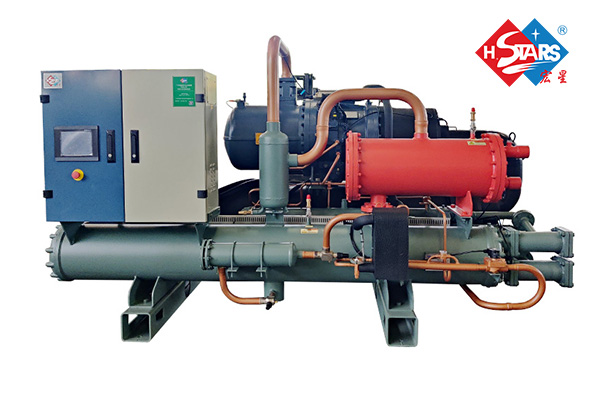

H.Stars Group with 30+ years of experience can help you with our advanced HVAC equipment, such as heat pump, air-cooled chiller, water-cooled chiller, Glycol Chiller and etc. If you would like to learn more about our products, please leave your inquiry on our website, and our sales team will contact you as soon as possible.