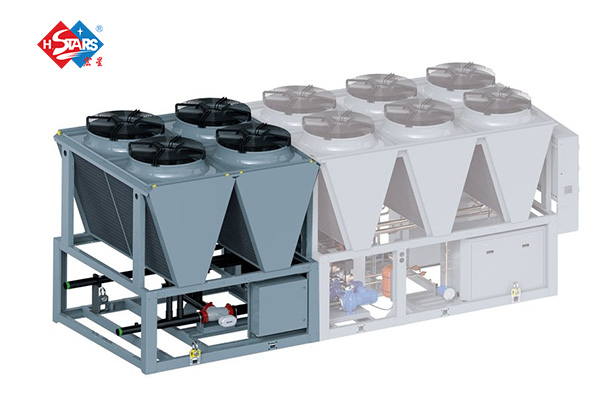

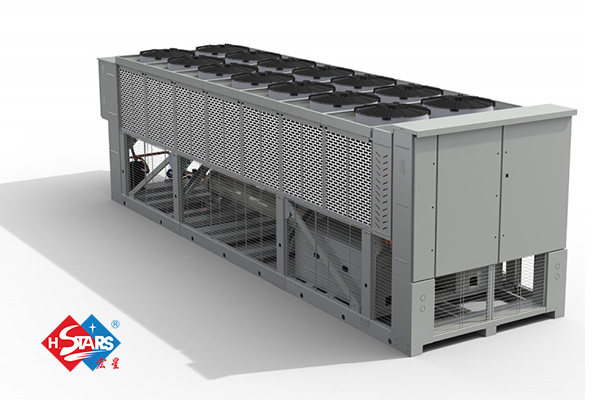

Free cooling chillers

Cooling is accomplished by drawing in outside air, passing it through a filter, and cooling it with water through a heat exchanger. The cooled air is then circulated through the facility. The system can also be used in reverse, drawing in air from the facility and cooling it before exhausting it outside. This helps to reduce the energy demands of the facility, as well as improve the overall comfort of the occupants.

Free cooling chillers utilize water or a water/glycol solution to collect and dissipate the heat from a chilled water loop. The chilled water loop is cooled by air or a water source, such as a river, lake, or well. The process of using the air or water to cool the chilled water loop is called free cooling. The chilled water loop is then used to chill the air or water that is used in the building. The water loop is pumped through the chiller, and the heat is dissipated by the water or glycol solution. The cool water is then circulated back into the building, where it provides cooling to the space. Free cooling chillers are a cost-effective way to reduce the need for mechanical cooling and reduce energy costs.

Free cooling chillers use outside air to cool the condenser in order to reduce the chiller’s energy consumption. When the outside air is cooler than the condenser’s leaving air temperature, the chiller will use either a direct air-cooled (DAC) or an evaporative condenser to cool the condenser. In a DAC system, outside air is drawn over the condenser coils, and the condenser fan is activated to circulate the air. In an evaporative condenser, outside air is drawn through a wetted media pad, and the air is cooled as it evaporates the water droplets on the pad. The cooled air is then drawn over the condenser coils, and the condenser fan is activated to circulate the air. The cooled condenser air is then used to reject heat from the refrigerant circulating through the condenser and the condenser is able to transfer the heat to the outside air more efficiently than when the outside air is warmer.

Related Tags :

Previous:

CO2 Heat PumpNext:

Variable Refrigerant Flow (VRF) systemCopyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy