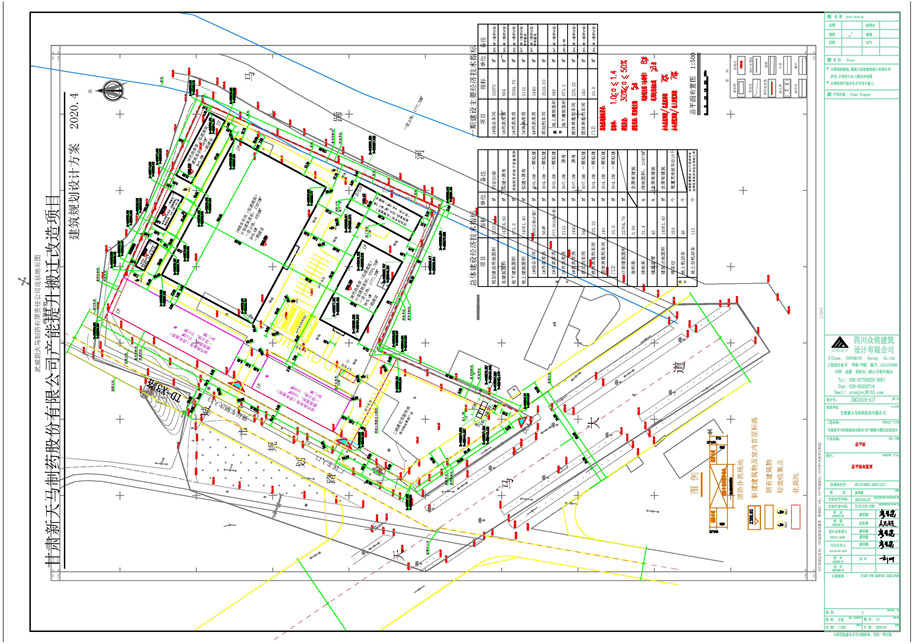

Project Overview

This project is a new workshop process cooling and purification air conditioning refrigeration station project for a pharmaceutical factory in Gansu, located in Wuwei Industrial Park, Liangzhou District,Wuwei City, Gansu Province. This project is a large infusion workshop, injection molding machine, mold and blow molding machine cooling, and large infusion workshop , Purification air conditioning in the tablet and granule workshop and process cooling such as workshop sterilization and pure water preparation. According to the process production requirements, this design includes the design content of workshop purification air conditioning, comfort air conditioning (cold and heating), and production line process cooling.

Project requirements

|

Items |

Air-conditioned area |

Air-conditioned area |

Summer cooling temperature requirements |

Heating temperature requirements in winter |

Cleanliness |

Cold load |

Heat load |

|

1 |

Tablet and granule workshop |

400㎡ |

24±2℃ |

18±2℃ |

Level D |

170kw |

100kw |

|

2 |

Large infusion workshop |

700㎡ |

24±2℃ |

18±2℃ |

Level C |

280kw |

175kw |

|

3 |

Canning room |

50㎡ |

24±2℃ |

18±2℃ |

Level Hundred |

50kw |

12.5kw |

|

4 |

Pre-treatment workshop |

550㎡ |

24±2℃ |

18±2℃ |

- |

146kw |

82.5kw |

|

5 |

Sterilization workshop and changing room |

1000㎡ |

24±2℃ |

18±2℃ |

- |

224kw |

150kw |

|

6 |

Reserved office area |

500㎡ |

24±2℃ |

18±2℃ |

- |

125kw |

75kw |

|

total: |

995kw |

595kw |

|||||

Design

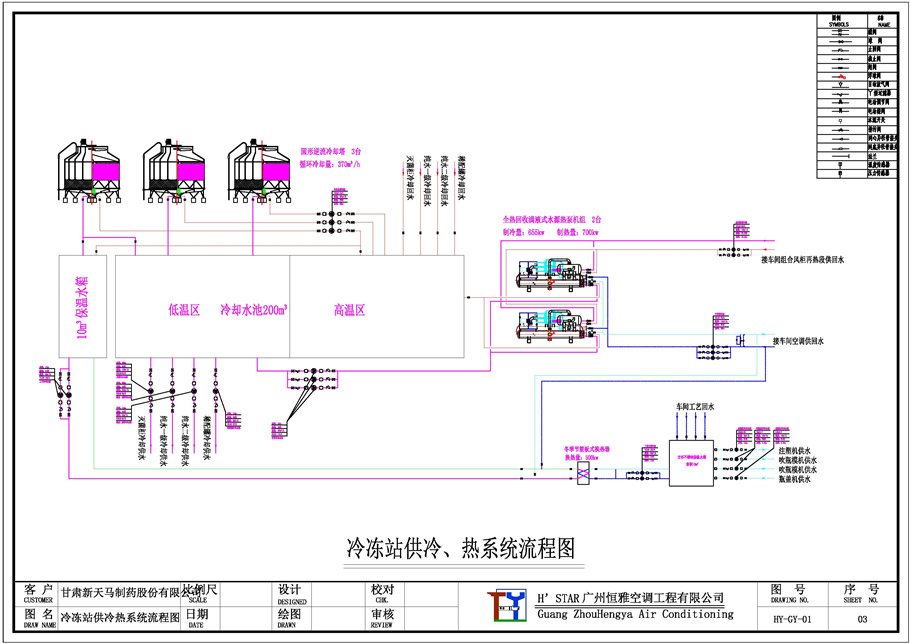

1.Air conditioning cooling and heating design instructions:

1.1. This project design uses two heat recovery flooded water source heat pump units, summer cooling capacity 655kw/unit, input power 103kw/unit, heat recovery capacity 400kw/unit, COP6.36; winter heating capacity 700kw/unit, input power 139kw/unit.

1.2. Operation description of flooded water source heat pump unit:

1.2.1. Summer: the condenser of the flooded water source heat pump unit is connected to the cooling pool, and the condensing heat of the unit is discharged through the cooling pool. At the same time, the free hot water generated by the heat recovery of the heat pump unit is supplied to the reheating section of the purification air cabinet of the workshop to reduce steam. Usage: the cold energy produced by the unit is supplied to the comfort air conditioner, purifying air conditioner and injection molding equipment in the workshop;

1.2.2. Winter: The evaporator of the flooded water source heat pump unit is connected to the cooling pool, and the unit absorbs heat from the cooling pool for heating, and the heat produced by the unit is supplied to the workshop's comfort air conditioning and purification air conditioning heating. Through design calculations, the heat contained in the cooling pool is 7000kw (the temperature of the pool drops from 35°C to 5°C), which can satisfy the continuous heating of the workshop for more than 14 hours;

3. Design instructions for workshop cooling water:

3.1. The project design uses three circular counterflow cooling towers with a circulating flow rate of 370m³/h/unit, motor power 11kw/unit, and a 200m³ cooling pool, which is divided into cold and hot zones. The cooling tower cools the pool in circulation.

3.2. The cooling of the sterilizer, distillation section and rare distribution tank in the workshop adopts a single water pump for one-by-one water supply, and the water pump adopts constant pressure frequency conversion control.

3.3. Cooling tower operation instructionsThe cooling tower starts and stops according to the pool temperature, and the pool temperature is higher than 35 degrees Celsius. When the ambient temperature is lower than 10 degrees Celsius, one of the cooling towers cools the small pool alone, and the water in the small pool cools the injection molding machine.

Project system diagram

Project configuration table

|

Product name |

The main parameters |

Quantity |

Remark |

|

Heat recovery flooded water source heat pump unit |

Cooling capacity:655KW Power:103kw Heating capacity:700kw, Power:139kw Heat recovery:400kw |

2set |

(Including reserved 500㎡ air conditioning cooling and heating load) |

|

Circular counterflow cooling tower |

Cooling water volume:370m³/h Fan power:11kw |

3set |

H.Stars |

|

Air conditioning circulating pump |

flow:140m³/h Head:33m Power:30kw |

3set |

Two use and one standby |

|

Combined air purifying machine for tablet and granule workshop |

Air volume:36000m³/h Cooling capacity:170kw Heating capacity:100kw Humidification amount:60kg/h With junior high efficiency filter residual pressure:900pa Fan power:22kw |

1set |

The fan is controlled by frequency conversion,the fresh air and return air are installed with electric valves, and the enthalpy difference is controlled. |

|

Combined clean air processor for large infusion workshop |

Air volume:55000m³/h Cooling capacity:140kw Heating capacity:132kw Humidification amount:75kg/h With junior high efficiency filter residual pressure:900pa Fan power:30kw |

2set |

The fan is controlled by frequency conversion, the fresh air and return air are installed with electric valves, and the enthalpy difference is controlled. |

|

Combined clean air processor for filling room |

Air volume:5000m³/h Cooling capacity:50kw Heating capacity:15kw Humidification amount:10kg/h With junior high efficiency filter residual pressure:250pa Fan power:2.2kw |

1set |

FFU full house laying |

|

Ceiling air handler for sterilization outsourcing room |

Air volume:12000m³/h Cooling capacity:101kw Heating capacity:158kw Residual pressure:250pa Fan power:4kw |

2sets |

Ceiling installation |

|

Combined clean air processor for pre-treatment workshop |

Air volume:8000m³/h Cooling capacity:86kw With junior high efficiency filter residual pressure:350pa Fan power:5.5kw |

2sets |

Floor installation |

Solution advantage

1.The heat recovery flooded water source heat pump unit is used for cooling in summer and heating in winter. At the same time, the heat recovery produces free reheating heat from the purified air conditioner. The unit has high energy efficiency ratio and comprehensive utilization rate, and low operating energy consumption, which is less than traditional cooling and heating equipment. Energy consumption is more than 50%, while reducing initial investment costs.

2. The heat supply source heat pump unit that recovers the process cooling water in the workshop can do two things with one stone. First, the heat pump unit has high heating efficiency in winter and low operating energy consumption (compared to boiler heating and air source heat pump heating, which can save 70%); second, heat pump The unit taking heat from the pool reduces the temperature of the cooling water in the pool, reduces the operating time of the cooling tower, and reduces operating costs.

3. The cooling water of the injection molding machine is provided by the heat pump unit in summer. When the ambient temperature is lower than 10℃, the cooling water of the injection molding machine is provided by the cooling tower, which reduces the running time of the heat pump host and reduces the operating cost. It is estimated that 320,000 kilowatts of electricity can be saved every year. Time.

4. All pump sets have a one-to-one correspondence with the refrigeration host, cooling tower, and terminal equipment to ensure that the entire system runs in the best mode and reduces operating costs.

5. The purification air cabinet increases the enthalpy difference control. By adjusting the valve ratio of the fresh air and the return air, the fresh air volume and the return air volume are controlled to reduce the cooling and heating requirements, reduce the running time of the heat pump host, and reduce the operating cost.

6. Add fan coils for cooling and heating in the computer room to ensure the normal operation of the equipment in the computer room throughout the year, reduce the use of glycol antifreeze, and reduce initial investment.

7. The main water pumps and cooling towers are equipped with frequency conversion devices, which operate according to temperature changes, reducing energy consumption and water costs.

8. This project has a central computer room with integrated design and centralized management to minimize investment costs and operating management costs.

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy