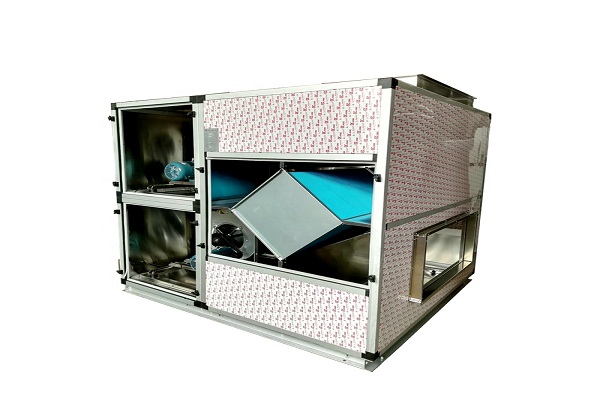

Heat Recovery Fresh Air Handling Unit

Main Features:

No pollution heat exchange: the

exchanger is made with modular structure, aluminium extruded sections,

aluminium coated Zinc plate, all the joints sealed by sealant, avoid

cross-polluted

- Operation efficiency and quietly, VFD fan available

- Outstanding reliability and performance

- Anti-corrosion stainless steel structure, clean hygienic design, durable

epoxy resin coated coil available

- Configured flexibly, numerous options for customization: cooling,

dehumidifying, heating and air clean function optional

Detailed Configuration:

Frame

• Penta-post extra heavy gauge aluminium profiles and strong fiber-reinforced PE corner connection forming the structural frame

• Superior mechanical strength and rigidity to the

unit frame and to prevent any buckling or deformation

• Thermal bridge free design, the profiles filled with polyurethane foam for

insulation

• Anodizing surface treatment for profiles, corrosion-resistant

• Stainless steel frame available

Casing Panel and Insulation

•

Double skin construction is provided by sandwich type panels comprising

inner and outer stainless steel skins and polyurethane foam with

minimum 48kg/m3 density, providing a good thermal and acoustical

performance

• The gasket liner between the panels and frame ensures the air leakage

rate to comply with GB/T 14294 clean air conditioning requirement

• The factory painted steel sheet covered with 6 insulation coatings,

complies to 500h salt spray testing, showing an excellent corrosion

protection performance

Famous Brand Blower and Motor

•

Fan selection based on the air flow and air static requirement is done by

fan selection software

• Direct driven/ belt driven, forward curve/ backward curve centrifugal

fans, and EC fan is available for option

• Nicotra, Kruger, Deton, Yilida is offered as option

• TEFC type motor, class F insulation and IP54 or IP55 protection, energy

saving and stable operation

• Mounted on an adjustable slide for belt tension adjustment

• Variable frequency drive (VFD) motor is available

• Siemens, ABB, WEG, TECO is offered as option

Vibration Eliminator

•

To reduce the transmission of vibration and noise, fan and motor are installed

on an independent complete base frame

• The complete base frame is isolated by deflection type spring isolators

• This unique structure not only reduce the vibration and noise, but also

protect fan and motor during transportation

High Efficiency Cooling and Heating Coil

•

All coils calculation and selection is done by selection software to match the

required conditions

• Large coil face area ensures maximum heat transfer rate

• All coils tested at 30bar pressure underwater 24 hours

• Various corrosion resistance coils for option:

-Cooper tube with cooper fins coil

-Epoxy coated fins coil

-Electrophoresis fins coil

-Heresite coated coil

Stainless Steel Drain Pan

• Slop type design, no drain water carryover

•

Avoid the micro-organisms growth inside the drain pan

Antimicrobial Drain Pan available upon application

• SteriTouch technology Dust Free Drip Pan Coating

• Antimicrobial surface

• Good exterior durability and corrosion resistance

• Non-toxic, comply with BS476 part 7

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy