Industrial Integrated All In One Chillers for Plastic Industry

Features of Industrial Integrated Chiller for Plastic Industry

1. Customization

H. Stars customizes the industrial integrated chiller unit based on various industries and projects and tailor-make integrated all in one industrial chiller to different clients.

2. Higher Energy Efficient

COP of 12℃ outlet water temperature higher (15~20%) than normal unit of 7℃ outlet water temperature, means energy-saving efficient.

3. Oversized Condenser and Evaporator

Oversized condensers not only make for a long lasting compressor, they

are also designed to operate in extreme conditions, i.e., above 45℃ and as low as -25℃, or at any temperature in between.

4. Heat Recovery

Supplying 55℃ free hot water, Heating Capacity approx. 1/3 of Cooling Capacity, increasing unit efficient about 5%.

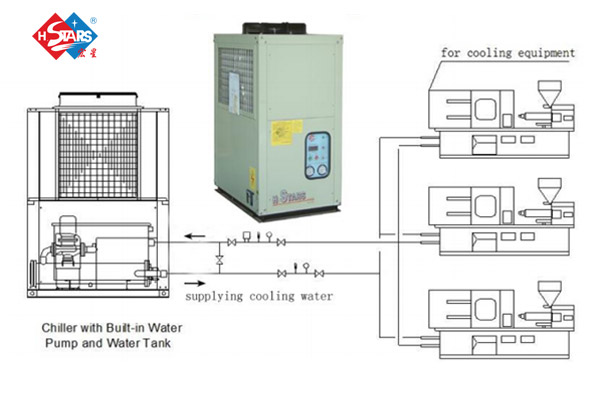

5. Integrated System

Built in water tank and water pumps module set (with valves and strainer assemble in a module), no piping and wiring errors, simple installation, save time and labor cost.

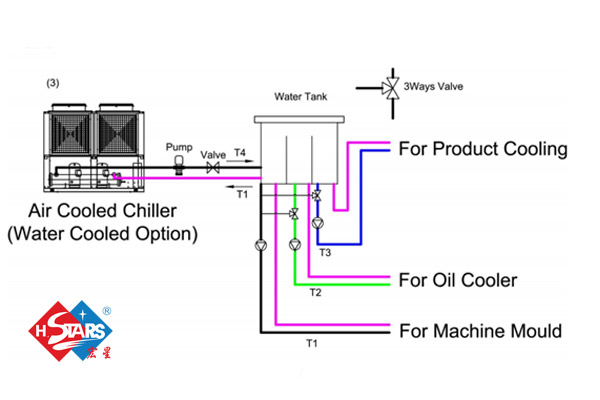

6. Water Tank

For supplying a stable outlet water temperature, also supplying multiple outlet water temperature to different cooling requirements application.

7. Water Pumps

With pump controller making unit reliable and easy operation.

8. Non-rusting Water Piping

Pipes can be plastic or stainless steel with galvanized steel fittings.

9. Safe and Reliable

The chiller has been designed with 7 safety protection to ensure the unit operation. Available in single and double circuit designs to meet different customer requests. In case one of the compressors fails, the other compressor can still be running, minimize the risk of whole system shutdown from losses.Each equipment will be 100% tested by national testing laboratory before shipping to ensure the chiller performance in accordance with national standards.

Technical Parameters of Water Cooled Industrial Chiller Units

|

|

05WCI |

10WCI |

12.5WCI |

15WCI |

20WCI |

||||||

|

|

R22 |

R407C |

R22 |

R407C |

R22 |

R407C |

R22 |

R407C |

R22 |

R407C |

|

|

Cooling Capacity |

*1000kcal/h |

14.6 |

15.1 |

31.5 |

30.3 |

36.7 |

36.8 |

46.4 |

45.5 |

62.9 |

60.6 |

|

kw |

17.0 |

17.5 |

36.6 |

35.2 |

42.7 |

42.8 |

53.9 |

53 |

73.2 |

70. 5 |

|

|

Input Power kw |

4.3 |

4.2 |

7.9 |

7.5 |

9.3 |

9.45 |

11.7 |

11.4 |

15.1 |

14.3 |

|

|

Compr Power kw |

3.55 |

3.4 |

6.8 |

6.4 |

7.8 |

7.95 |

10.2 |

9.9 |

6.8*2 |

6.4*2 |

|

|

Water Pump |

HD1.0DK-20 |

HD40-15 |

HD50-17 |

HD50-17 |

HD50-17 |

||||||

|

Water Pump Power kw |

0.75 |

1.1 |

1.5 |

1.5 |

1.5 |

||||||

|

Current A |

8.4 |

8 |

16.2 |

15.5 |

18.1 |

18.1 |

22.8 |

22.1 |

31.1 |

29.7 |

|

|

Power Supply |

3P-380V-50Hz |

||||||||||

|

Product Device |

Compr Over Temperature, Compr Over Current, High&Low Pressure, Flow Switch, Anti-freezing, Exhaust, Phase Missing, Overheating |

||||||||||

|

Refrigerant Circuit |

1 |

2 |

|||||||||

|

Capacity Control % |

0,100 |

0,50,100 |

|||||||||

|

Condenser |

Shell and Tube Type |

||||||||||

|

Chilled Water Flow L/min |

58.9 |

59.9 |

124.3 |

119.4 |

144.8 |

145.5 |

183.7 |

180.1 |

248.6 |

238.8 |

|

|

Evaporator |

Coil Type |

Shell and Tube Type |

|||||||||

|

Cooling Water Flow L/m |

48.7 |

50.2 |

104.9 |

101.0 |

122.4 |

122.7 |

154.5 |

151.8 |

209.7 |

202.0 |

|

|

Running Noise dB(A) |

52 |

63 |

65 |

67 |

68 |

||||||

|

Water Tank L |

80 |

180 |

180 |

180 |

270 |

||||||

|

Weight kg |

150 |

440 |

480 |

520 |

680 |

||||||

Notes:

1. These are our standard chiller units, our factory accept produce non-standard unit according to your specification(inlet/out water temperature, power supply, refrigerant, etc.)

2. Rated Cooling Capacity Base: Chilled Water In/Outlet 17°C/12°C, Cooling Water In/Outlet: 30/35°C ,Air ambient: 35°C, fouling factor: 0.088m²•°C/KW;

3. Chilled Water Range: 5~ 20°C;

4. Cooling Water Range: 15 ~ 40°C;

5. Changes of Specification for improvement may be made without notice.

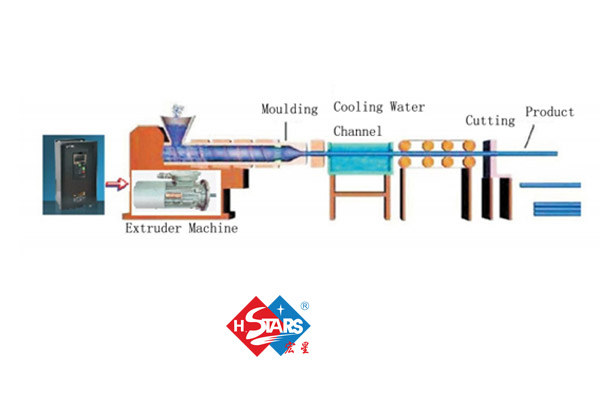

Cooling system drawings