How to measure brine concentration for the brine chiller ?

Saltwater brine chillers are also one of the more commonly used refrigeration equipment. Its refrigerant is the so-called brine solution, which has a low freezing point. It is especially suitable for medium and low temperature chillers to carry cold capacity. The temperature is generally required to be controlled at 0 Below ℃, it is usually used for the low-temperature requirements of some special production lines in the industry. So, what kind of harm will the improper proportion of brine-carrying refrigerant cause to the chiller and how to measure brine concentration for the brine chiller ?

The refrigerant is an intermediate substance used to transfer the cold heat generated by the refrigerator to the object to be cooled or heated. Commonly used refrigerants include air, water, saltwater, organic compounds, and their aqueous solutions; when the outlet water temperature is 0°C, the commonly used water-borne refrigerants will be frozen. At this time, a suitable refrigerant must be selected, such as saltwater, Ethylene glycol, etc., the selection principle is first that the refrigerant in the heat exchanger does not be frozen.

How to measure brine concentration for the brine chiller ?

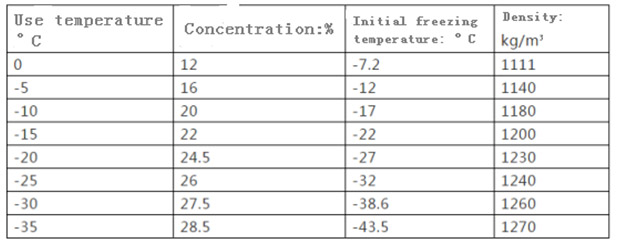

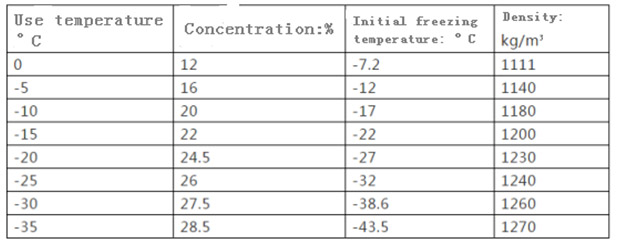

Salt water carrier refrigerant use temperature and ratio mass concentration table

1. The salt water concentration is too high or too low.

If the brine concentration is increased and the specific heat is reduced, the power consumption of the chiller pump of the chiller will increase, and the relative cost will also increase; if the concentration is too small to reach the standard, this may cause the heat exchanger to freeze, the unit alarm can not work normally and affects normal production. Therefore, when we use salt water as the refrigerant carrier of the brine low-temperature chiller, we must pay attention to the ratio of the brine carrier refrigerant.

2. The corrosiveness of salt water to low-temperature chillers and pipelines.

If the oxygen content in the solution decreases, its corrosiveness to brine low temperature chillers and pipelines will slow down. Based on this, we can adopt a closed salt water system to reduce the principle of contact between salt water and air, so as to reduce the corrosion of low-temperature chillers and pipelines. In addition, you can also reduce the corrosiveness by adding preservatives to the salt water to make it have suitable acidity and alkalinity.

When the density of brine carrier refrigerant decreases.

The brine-carrying agent will absorb moisture in the air during use, which will reduce its concentration and cause the freezing point to rising. Therefore, in the process of using the brine cryogenic chiller, the density of the brine should be checked regularly. If the density appears To reduce the phenomenon, the amount of salt can be supplemented appropriately to maintain the concentration of brine.

For more details, welcome to contact us at sales@hstars.com.cn