Explosion-proof Water Cooled Chiller has the characteristics of explosion-proof, increased safety, oil-filled, sand-filled, non-sparking, potting and airtight, etc., which is suitable for self-enclosed indoor space environment with explosive gas mixture in the air.

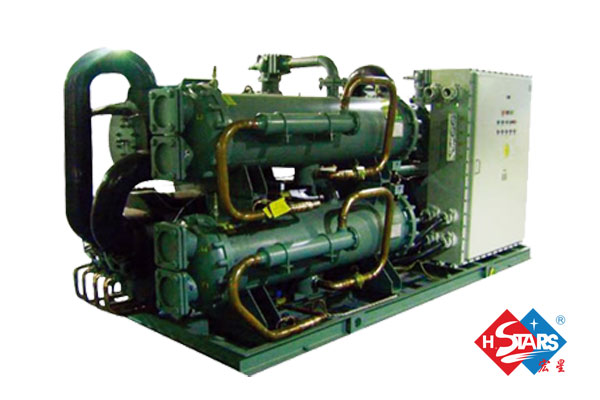

Explosion-proof unit (explosion-proof chiller)

Introduction: Open type industrial explosion-proof chillers adopt explosion-proof, increased safety, intrinsically safe, positive pressure, oil-filled, sand-filled, non-sparking, potting and airtight, etc., so that the unit can be used in flammable and explosive places.

Brand: H.Stars

Refrigeration range: custom

Applications: Chemicals and other industries with explosion-proof requirements

Explosion-proof unit (explosion-proof chiller) parameters:

Cooling (heat): 21500kcal/h or more

Indoor/outdoor noise: ≤40/≤59

Scope of application: It is suitable for self-enclosed indoor space environment with explosive gas mixture in the air such as petroleum, chemical, metallurgy, pharmaceutical and defense industries as air purification and temperature regulation (lower temperature or elevated temperature).

Explosion-proof unit (explosion-proof chiller) features:

The unit is mainly composed of explosion-proof compressor, heat exchanger, explosion-proof four-way solenoid valve, potted pressure switch and explosion-proof motor and explosion-proof electrical control box.

[Explosion-proof unit (explosion-proof chiller) installation requirements]

(1) The air conditioner can work normally under the following environmental conditions:

a. The height of the altitude does not exceed 2000m;

b. Ambient temperature: indoor cooling 17 ° C ~ 32 ° C, outdoor 18 ° C ~ 43 ° C, heating: indoor not higher than 30 ° C, outdoor -7 ° C ~ +24 ° C;

c. Relative humidity of air: during the wet month, the monthly average relative humidity is not more than 90%; at the same time, the monthly average low temperature is not higher than +25 °C;

d. Zone 1 and Zone 2 hazardous sites with explosive gas (or liquid or steam) of Groups II and IIB T1~T4;

f. Places where there is no severe vibration and impact;

g. In a clean environment without dust and water.

(2) The air conditioner should be properly installed by qualified installation technicians in accordance with the correct installation instructions in this manual.

(3) Check the power supply voltage before installation and whether the environmental conditions are consistent with the requirements on the nameplate.

(4) The installation location of the air conditioner should avoid the adverse effects of soot, heat radiation and humidity.

(5) The installation location of the outdoor unit should avoid the direct infiltration of moisture, sea water, wind, rain and sun, and take precautionary measures if necessary.

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy