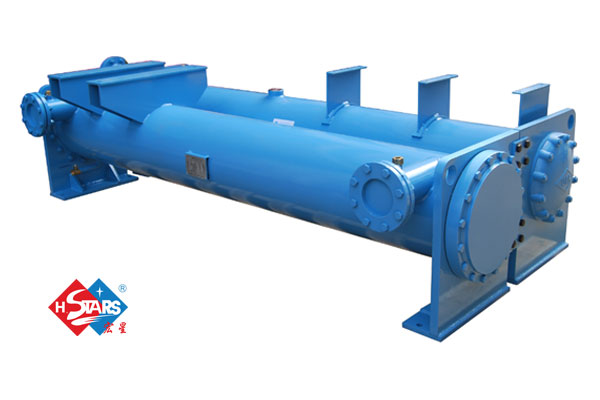

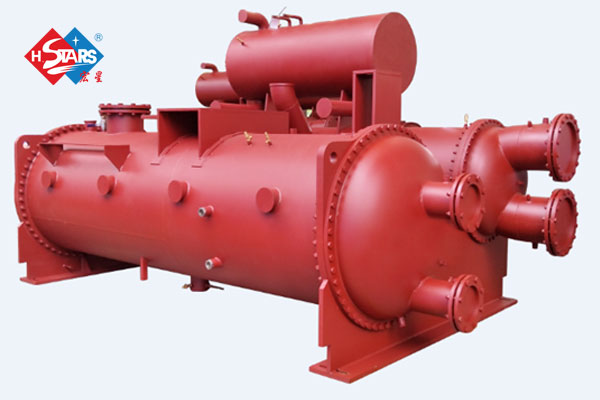

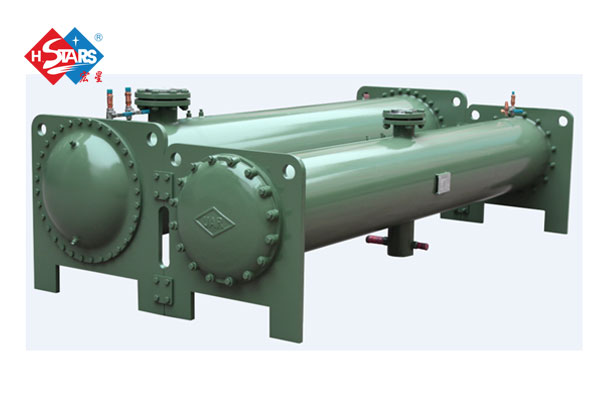

Manufacturers Modular Combination Industrial Assembled Shell and Tube Heat Exchanger

The modular combination industrial assembled shell and tube heat exchanger has the advantages of simple structure, fast and efficient heat exchange and convenient operation. The integrated design of assembled shell and tube heat exchangers can greatly save the installation time and labor cost of replacing heat exchanger of maintenance unit.

The shell of modular evaporator + condenser is made of steel pipe with thickness of more than 5mm. After antirust treatment, the pressure resistance is 25kg / cm2. The heat exchange pipe is made of high efficiency seamless copper tube with pressure resistance of 10kg / cm2.

The shell strength calculation of double machine system condenser is based on the authoritative pressure vessel design software sw6-2011 developed by the national chemical equipment design technology center station in China. The sw6-2011 software package takes the GB 150-2011 and other standards as the calculation model and windows as the operation platform. The thickness of shell can meet the strength requirement of product design pressure.

Company information

UAR as one of the biggest specialized shell and tube heat exchanger manufacturers in Guangzhou,China, producing industrial heat exchanger and heat exchanger in hvac since 1996.

How to remove scale in modular evaporator + condenser

The specific operation method of module evaporator + condenser for scale removal is: remove the condenser, drain the water, and then inject 10% dilute sulfuric acid solution into the switch until there is a solution outflow position at the water outlet. Dilute sulfuric acid can be discharged after staying in the condenser for 20-30min. Repeat this for two or three times. Then install the connecting pipe between the cooling water pipe and the condenser, open the cooling water valve and wash for 10-20min, and the anti-scaling and cleaning work will be finished.

Copyright © 2015-2026 H.Stars (Guangzhou) Refrigerating Equipment Group Ltd.

/ Blog / Sitemap / XML / Privacy-policy